Page content:

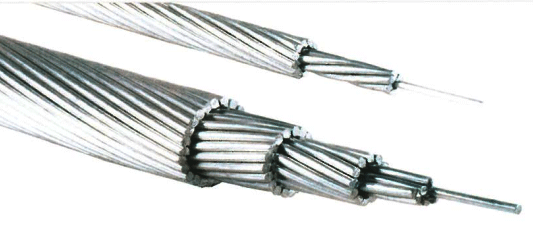

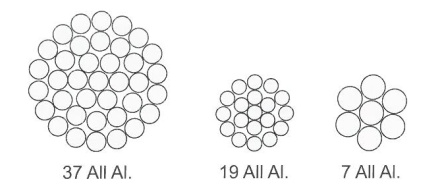

All Aluminium Conductor-AAC

- Standard:

lEG 61089 Type A1

Construction:

All-Aluminum conductors are the most favored type for use in the construction of relatively short span distribution schemes and are in common use on lines for voltages up to 63 KV. Another frequent application for all – Aluminum conductor is in flexible busbar connections. Although aluminum-to-copper connection can be made, it is better to use aluminum conductors for service connections, various forms cable being available for this purpose. The data sheets show the most common sizes of conductor but other sizes, related to any recognized specification, can be supplied.

- Application:

These conductors have great economical advantage when compared with copper type bare conductors and Insulated cables regarding installation of overhead distribution lines at low and medium voltages.

Code number | Area (mm2) | No. of Wires (No) | Dia. of Wires (mm) | Weight (kg/km) | Rated Strength (KN) | D.C. resistance (ohm/km) |

|---|---|---|---|---|---|---|

10 | 10 | 7 | 1.35 | 27.4 | 1.95 | 2.8633 |

15 | 15 | 7 | 1.71 | 43.8 | 3.04 | 1.7896 |

25 | 25 | 7 | 2.13 | 68.4 | 4.50 | 1.1453 |

40 | 40 | 7 | 2.70 | 109.4 | 6.80 | 0.7158 |

63 | 63 | 7 | 3.39 | 172.3 | 10.39 | 0.4545 |

100 | 100 | 19 | 2.59 | 274.8 | 17.00 | 0.2877 |

125 | 125 | 19 | 2.89 | 343.6 | 21.25 | 0.2302 |

160 | 160 | 19 | 3.27 | 439.8 | 26.40 | 0.1798 |

200 | 200 | 19 | 3.66 | 549.7 | 32.00 | 0.1439 |

250 | 250 | 19 | 4.09 | 687.1 | 40.00 | 0.1151 |

315 | 315 | 37 | 3.29 | 867.9 | 51.97 | 0.0916 |

400 | 400 | 37 | 3.71 | 1102.0 | 64.00 | 0.0721 |

450 | 450 | 37 | 3.94 | 1239.8 | 72.00 | 0.0641 |

500 | 500 | 37 | 4.05 | 1377.6 | 80.00 | 0.0577 |

560 | 560 | 37 | 4.39 | 1542.9 | 89.60 | 0.515 |

630 | 630 | 61 | 3.63 | 1738.3 | 100.80 | 0.0458 |

710 | 710 | 61 | 3.85 | 1959.1 | 113.60 | 0.0407 |

800 | 800 | 61 | 4.09 | 2207.4 | 128.00 | 0.0361 |

900 | 900 | 61 | 4.33 | 2483.3 | 144.00 | 0.0321 |

1000 | 1000 | 61 | 4.57 | 2759.2 | 160.00 | 0.0289 |

1120 | 1120 | 91 | 3.98 | 3093.5 | 179.20 | 0.0258 |

1250 | 1250 | 91 | 8.14 | 3452.6 | 200.00 | 0.0231 |

1400 | 1400 | 91 | 4.43 | 3866.9 | 224.00 | 0.0207 |

1500 | 1500 | 91 | 4.58 | 4143.1 | 2440.00 | 0.0193 |

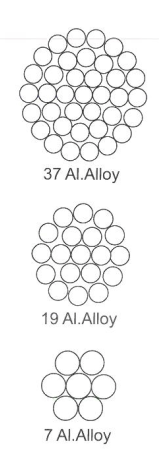

All Aluminium Alloy conductor - AAAC

- Standard:

German Standard DIN 48201

Construction:

These conductors are formed by several of these, with other wires of galvanized steel, stranded in concentric layers. The central wire which from the core are of either alloy or steel and the outer layers are of alloy. Normally the composition of these conductors is the same as the ones pertaining to the aluminum steel conductors. In the case of alloy conductors, all the wire can be the same nominal diameter and in the case of alloy conductors with a steel core, the diameters of the alloy and the steel wire can be the’ same or different of one other. The basic composition of this alloy pertains to the aluminum – magnesium – silicon group which is also known in Europe as Alrnelec Aldery and after their drawing they must undergo a thermal treatment at a temperature of approximately 165°C.

- Application:

As regards aluminum, the wire of this alloy has a double tensile strength (greater than 30kg/mm2), its electrical conductivity is 15% lower (53% instead of 61%) and the weight is the same. By making use of these characteristics, in many cases, an alloy conductor can be replaced the Aluminum conductor steel reinforced with a similar installation cost. The Aluminum Alloy steel reinforced conductors have a much higher strength and low, medium, high and very high voltage lines.

Code Number Nominal (mm2) | Code Number Actual (mm2) | Stranding and Wire diameter (No./mm) | Overal Diameter (mm) | Weight (kg/km) | Nominal Breaking Load (kp) | Maximum DC resistance at 200^C (ohm/km) | Maximum AC Resistance 25^C (ohm/km) | Maximum AC Resistance 75^C (ohm/km) | Current Rating Ambient Temp 25^C (A) | Current Rating Ambient Temp 40^C (A) |

|---|---|---|---|---|---|---|---|---|---|---|

16 | 15.89 | 7/1.7 | 5.1 | 43 | 453 | 2.09127 | 2.13350 | 2.55490 | 96 | 80 |

25 | 24.25 | 7/2.1 | 6.3 | 66 | 691 | 1.37047 | 1.39827 | 1.67445 | 127 | 106 |

35 | 34.36 | 7/2.5 | 7.5 | 94 | 979 | 0.96700 | 0.98715 | 1.18213 | 160 | 134 |

50 | 49.46 | 7/3.0 | 9.0 | 135 | 1409 | 0.67153 | 0.68552 | 0.82092 | 206 | 170 |

50 | 48.36 | 19/1.8 | 9.0 | 133 | 1377 | 0.69063 | 0.70502 | 0.84427 | 201 | 168 |

70 | 65.82 | 19/2.10 | 10.5 | 181 | 1875 | 0.50740 | 0.51797 | 0.62028 | 246 | 206 |

95 | 93.27 | 19/2.50 | 12.5 | 256 | 2657 | 0.35802 | 0.36601 | 0.43831 | 310 | 260 |

120 | 117.00 | 19/2.80 | 14.0 | 322 | 3333 | 0.28541 | 0.29178 | 0.34941 | 361 | 303 |

150 | 147.10 | 37/2.25 | 15.7 | 405 | 4191 | 0.22742 | 0.23279 | 0.27888 | 420 | 352 |

185 | 181.60 | 37/2.50 | 17.5 | 500 | 5174 | 0.18421 | 0.18890 | 0.22621 | 483 | 405 |

240 | 242.53 | 61/2.25 | 20.2 | 670 | 6909 | 0.13835 | 0.14265 | 0.17082 | 584 | 489 |

300 | 299042 | 61/2.50 | 22.5 | 827 | 8530 | 0.11206 | 0.11600 | 0.13891 | 671 | 562 |

400 | 400.13 | 61/2.89 | 26.0 | 1105 | 11398 | 0.08386 | 0.08839 | 0.10585 | 807 | 676 |

500 | 499.82 | 61/3.23 | 29.1 | 1381 | 14238 | 0.06713 | 0.07137 | 0.08546 | 932 | 781 |

625 | 626.28 | 91/2.96 | 32.6 | 1733 | 17838 | 0.05369 | 0.05830 | 0.06981 | 1071 | 898 |

800 | 802.06 | 91/3.35 | 36.8 | 2226 | 22848 | 0.04192 | 0.04752 | 0.05691 | 1237 | 1036 |

1000 | 999.68 | 91/3.74 | 41.1 | 2767 | 28477 | 0.03367 | 0.04037 | 0.04835 | 1393 | 1166 |

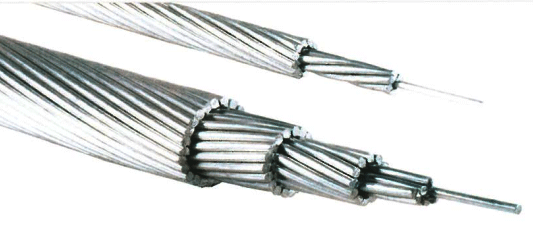

Aluminum Conductor Steel Reinforced - ACSR-GA

- Standard:

British Standard BS 215 Part 2

Construction:

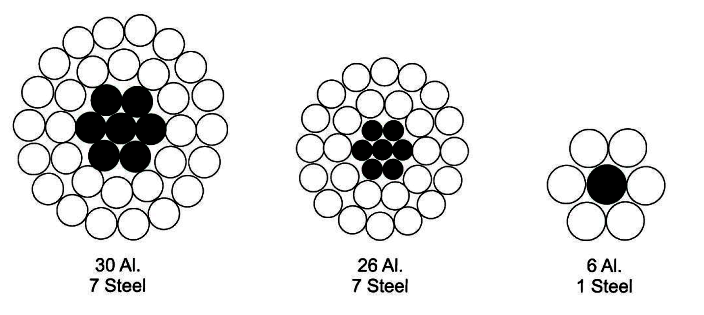

Aluminum Conductors Consist of several wires of Aluminum and galvanized high carbon steel, stranded in concentric layers, the wire or wires which form the core are made galvanized steel core of 1,7 or 19 wires, Surrounded by concentric layers of Aluminum wires.

- Application:

The Aluminum conductors (ACSR) are suitable for over head lines of medium, high and extra high voltages for short or long distances.

Code Name | Area Aluminum Nominal | Area Aluminum (mm2) | Area Steal (mm2) | Area Taoist (mm2) | Stranding and Wire Diameter Aluminum (No./mm) | Stranding and Wire Diameter Steal (No./mm) | Apptcoxmate Derail Diameter (mm) | Weight Aluminum (kg/km) | Weight Steal (mm2) | Weight Taoist (mm2) | Nominal Breaking Load (mm) | Maximum DC Resistance at 20°C (mm) | Maximum AC Resistance at 25°C (ohm/km) | Maximum AC Resistance at 75°C (ohm/km) | Quran Rating Arians Tempo 25°C (A) | Quran Rating Arians Tempo 40°C (A) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Mole | – | 10.60 | 1.77 | 12.37 | 6/1.50 | 1/1.50 | 4.5 | 29 | 14 | 43 | 421 | 2.63987 | 2.69317 | 3.22513 | 82 | 69 |

Squirrel | – | 2098 | 3.50 | 24.48 | 62.11 | 1/2.11 | 6.33 | 58 | 27 | 85 | 806 | 1.3414 | 1.36120 | 1.63006 | 129 | 108 |

Gopher | 25 | 26.25 | 4.37 | 30.62 | 6/2.36 | 12.36 | 7.08 | 72 | 34 | 106 | 980 | 1.06645 | 1.08808 | 1.30300 | 149 | 135 |

Weasel | 30 | 31.61 | 5.27 | 36.88 | 6/2.59 | 12.59 | 7.77 | 87 | 41 | 128 | 1157 | 0.88545 | 0.90358 | 1.082206 | 169 | 141 |

Fox | – | 3668 | 6.11 | 42.79 | 6/2.79 | 12.79 | 8.37 | 101 | 48 | 148 | 1343 | 0.76306 | 0.77868 | 0.93249 | 186 | 165 |

Ferret | 40 | 42.41 | 7.07 | 49.48 | 6/3.00 | 1/3.00 | 9 | 116 | 55 | 171 | 1553 | 0.65997 | 0.67348 | 0.80651 | 205 | 172 |

Rabbit | 50 | 52.88 | 8.81 | 61.70 | 6/3.35 | 1/3.35 | 10.05 | 145 | 69 | 214 | 1873 | 0.52927 | 0.5429 | 0.64701 | 238 | 199 |

Mink | – | 63.12 | 10.52 | 73.64 | 6/3.66 | 1/3.66 | 10.98 | 173 | 82 | 255 | 2223 | 0.44341 | 0.45289 | 0.54234 | 267 | 224 |

Shrunk | – | 63.22 | 36.88 | 100.10 | 12/2.59 | 7/2.59 | 12.95 | 175 | 288 | 483 | 5378 | 0.42001 | 0.46076 | 0.55176 | 290 | 243 |

Beaver | – | 75.02 | 12.50 | 87.52 | 6/3.99 | 1/3.99 | 11.97 | 206 | 97 | 303 | 2627 | 0.3709 | 0.38107 | 0.45634 | 300 | 251 |

Horse | 70 | 73.36 | 42.79 | 116.16 | 12/2.79 | 7/2.79 | 13.95 | 203 | 334 | 537 | 6240 | 0.36195 | 0.39706 | 0.47549 | 321 | 269 |

Recon | – | 79.21 | 13.20 | 92.42 | 6/4.10 | 1/4.10 | 12.3 | 217 | 103 | 320 | 2774 | 0.35334 | 0.36123 | 0.43258 | 311 | 261 |

Otter | – | 83.92 | 13.99 | 97.90 | 6/4.22 | 1/4.22 | 12.66 | 230 | 109 | 339 | 2930 | 0.33353 | 0.34098 | 0.40833 | 323 | 271 |

Cat | – | 95.42 | 15.90 | 111.33 | 6/4.50 | 1/4.50 | 13.5 | 262 | 124 | 386 | 33.41 | 0.29332 | 0.29986 | 0.35909 | 352 | 295 |

Hare | – | 104.98 | 17.50 | 122.43 | 6/4.72 | 1/4.72 | 14.16 | 288 | 136 | 424 | 3665 | 0.26661 | 0.27291 | 0.2368 | 376 | 314 |

Dog | 100 | 104.98 | 13.55 | 118.53 | 6/4.72 | 7/1.57 | 14.15 | 288 | 106 | 394 | 3333 | 0.26811 | 0.27896 | 0.33406 | 374 | 313 |

Hyena | – | 105.96 | 20.48 | 126.43 | 7/4.39 | 7/1.93 | 14.57 | 291 | 160 | 451 | 4194 | 0.26316 | 0.27602 | 0.33054 | 381 | 319 |

Leopard | – | 13137 | 16.84 | 148.21 | 6/5.28 | 7/1.75 | 15.81 | 360 | 132 | 492 | 4157 | 0.21432 | 0.22338 | 0.28748 | 433 | 363 |

Coyote | – | 131.74 | 20.06 | 151.80 | 26/2.54 | 7/1.91 | 15.89 | 364 | 156 | 510 | 4684 | 0.21443 | 0.22417 | 0.26845 | 434 | 364 |

Cougar | – | 131.51 | 7.31 | 138.81 | 18/3.05 | 1/3.05 | 15.25 | 362 | 58 | 420 | 3116 | 0.21717 | 0.22270 | 0.26669 | 425 | 355 |

Tiger | – | 131.23 | 30.62 | 161.85 | 30/2.36 | 7/2.36 | 16.52 | 363 | 239 | 602 | 5916 | 0.21273 | 0.22466 | 0.26903 | 441 | 370 |

Wolf | 150 | 158.05 | 36.88 | 194.93 | 30/2.59 | 7/2.59 | 18.13 | 437 | 288 | 725 | 7061 | 0.17663 | 0.18697 | 0.22391 | 499 | 419 |

– | 150 | 158.65 | 8.81 | 167.46 | 18/3.35 | 1/3.35 | 16.75 | 437 | 69 | 506 | 3460 | 0.1900 | 0.18502 | 0.22155 | 481 | 403 |

Lynx | 175 | 184.23 | 10.24 | 194.47 | 18/3.61 | 1/3.61 | 18.05 | 508 | 80 | 558 | 3983 | 0.15501 | 0.15933 | 0.19080 | 551 | 462 |

– | 175 | 184.23 | 10.24 | 194.47 | 18/3.61 | 1/3.61 | 18.05 | 508 | 80 | 558 | 3983 | 0.15501 | 0.15933 | 0.19080 | 532 | 446 |

Code Name | Area Aluminum Nominal | Area Aluminum (mm2) | Area Steal (mm2) | Area Taoist (mm2) | Stranding and Wire Diameter Aluminum (No./mm) | Stranding and Wire Diameter Steal (No./mm) | Apptcoxmate Derail Diameter (mm) | Weight Aluminum (kg/km) | Weight Steal (mm2) | Weight Taoist (mm2) | Nominal Breaking Load (mm) | Maximum DC Resistance at 20°C (mm) | Maximum AC Resistance at 25°C (ohm/km) | Maximum AC Resistance at 75°C (ohm/km) | Quran Rating Arians Tempo 25°C (A) | Quran Rating Arians Tempo 40°C (A) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Panther | 200 | 21205 | 49.48 | 261.53 | 30/2.00 | 7/3.00 | 21 | 586 | 387 | 973 | 9408 | 0.13165 | 0.13979 | 0.16740 | 806 | 509 |

Lion | – | 238.26 | 55.59 | 293.85 | 30/3.18 | 7/3.18 | 22.26 | 658 | 435 | 1083 | 10247 | 0.11717 | 0.12491 | 0.14958 | 654 | 549 |

Bear | – | 264.42 | 61.70 | 326.11 | 30/3.35 | 7/3.35 | 26.45 | 731 | 482 | 1213 | 11345 | 0.10558 | 0.11310 | 0.18544 | 700 | 587 |

Goat | – | 324.30 | 75.67 | 399.97 | 30/3.71 | 7/3.71 | 25.97 | 896 | 591 | 1488 | 13848 | 0.08608 | 0.09277 | 0.1110 | 799 | 671 |

Sheep | – | 3750.10 | 87.52 | 462.62 | 30/3.99 | 7/3.99 | 27.93 | 1036 | 684 | 1721 | 15940 | 0.07442 | 0.08079 | 0.09675 | 878 | 736 |

Antelope | – | 374.10 | 48.49 | 422.59 | 54/2.97 | 7/2.97 | 26.73 | 1015 | 379 | 1394 | 12087 | 0.07445 | 0.07975 | 0.9550 | 865 | 725 |

Bison | – | 381.69 | 49.48 | 431.17 | 54/3.00 | 7/3.00 | 27 | 1036 | 337 | 1423 | 12130 | 0.07297 | 0.07817 | 0.09360 | 876 | 736 |

– | 200 | 210.63 | 11.70 | 222.33 | 18/3.86 | 1/3.86 | 19.3 | 580 | 91 | 672 | 4513 | 0.13558 | 0.14291 | 0.1713 | 674 | 481 |

Deer | – | 429.59 | 100.24 | 529.83 | 300/4.27 | 7/4.27 | 29.89 | 1187 | 783 | 1971 | 18212 | 0.06498 | 0.07114 | 0.08520 | 957 | 803 |

Zebra | 400 | 428.87 | 55.59 | 484.465 | 54/3.18 | 7/3.18 | 28.62 | 1164 | 435 | 1599 | 13454 | 0.06494 | 0.07016 | 0.08402 | 943 | 791 |

Elk | – | 477.12 | 111.33 | 588.44 | 30/4.50 | 7/4.50 | 31.5 | 1318 | 870 | 2189 | 20227 | 0.5851 | 0.06469 | 0.07747 | 1022 | 857 |

Camel | – | 475.95 | 61.7 | 537.65 | 54/3.35 | 7/3.35 | 30.15 | 1292 | 482 | 1774 | 14883 | 0.05852 | 0.06385 | 0.07747 | 1006 | 844 |

Moose | – | 528.47 | 68.5 | 596.98 | 54/3.53 | 7/3.53 | 31.77 | 1434 | 685 | 1970 | 16417 | 0.6270 | 0.05816 | 0.06985 | 1073 | 900 |

Aerial Cables

Type 1: SINGLE PHASE SELF SUPPORTING CABLE WITH ACSR CORE ( 0.6/1KV) NA2X-T

- construction:

Conductor : Aluminum ( phase and lighting ), ACSR ( neutral and messenger)

insulation: XLPE

- abbreviation: AL/XLPE , ACSR/XLPE

- standard: TAVANIR, NFC 33-209

TYPE 2: 3 PHASE SELF SUPPORTING CABLE WITH ACSR CORE ( 0.6/1KV ) NA2X-T

- construction:

Conductor : Aluminum ( 3 phases, and lighting )) ACSR ( neutral and messenger)

insulation: XLPE

abbreviation: AL/XLPE , ACSR/XLPE

standard: TAVANIR, NFC 33-209

TYPE 3: 3 PHASE SELF SUPPORTING CABLE WITH NEUTRAL AND LIGHTING CORE (0.6/1KV)TYPE 2 NA2X-T

- construction:

Conductor : Aluminum ( 3 phases, neutral and lighting ), galvanized steel wires (messenger)

Insulation: XLPE

- abbreviation: AL/XLPE

- standard: TAVANIR, NFC 33-209

TYPE4: 3 PHASE SELF-SOPPORTING CABLE WITH LIGHTING, NAUTRAL – MESSENGER AL-ALLOY NA2X-T

- construction:

Conductor : Aluminum (phase and lighting) al-alloy (messenger – neutral)

Insulation: XLPE

- abbreviation: AL/XLPE

- standard: TAVANIR, NFC 33-209

Type 5: MEDIUM VOLTAGE SELF SUPPORTING CABLES 3 PHASE 20KV CABLES WITH INDIVIDUAL MESSENGER

- construction:

Conductor: stranded and compacted Aluminum conductor screen and insulation screen : extruded semi conductor Insulation: dry cured XLPE

Outer covering of each core: uv resistant PVC

Messenger: steel wires

Insulation of messenger: uv resistant PVC

abbreviation:

AL/SC/XLPE/SC/SC TAPE/CWS/PET/PVC

standard: IEC 60502-2, IEC 60228

آدرس دفتر تهران: خیابان شهید بهشتی، نبش میرعماد، ساختمان زمرد، طبقه دوم

تلفن:02188752014

فکس:02188757639