Page content:

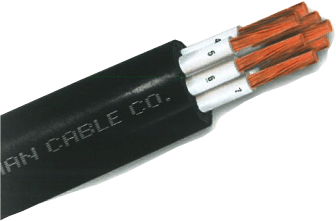

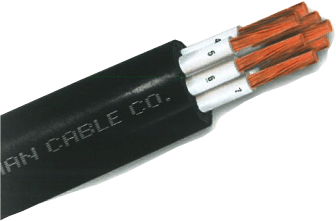

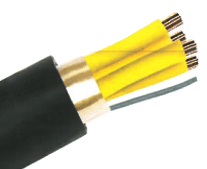

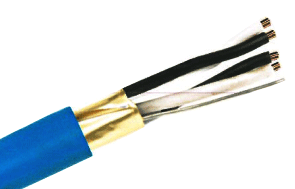

Flexible Unscreened Cable NYSLYO

- Voltage Rate: 300-500 V

Applicable Standard: IEC 60227, IEC 60228

- Code Designation Of Wire According IEC: 60227 IEC 75

Construction:

Conductor: Plain Annealed Copper Wire or Tin Coated Wires(Class 5)

Insulation Type: P.V.C/D

Outer Sheath Type: P.V.C/ST9

Maximum Conductor Temperature: 70°C

- Application:

Suitable for internal/external wiring of electrical equipment at medium mechanical stress, in dry and damp interiors as well as in industrial environments. Theses cables can be used in machine tool manufacturing, machines, devices, office machine, data processing and as a control cable for static and flexible but not for continusly flexible application where electrical protection is not required.

No. of Cores & Cross Section (mm2) | Nominal insulation Thickness (mm) | Nominal Sheath Thickness (mm) | Overall Dia. (Approx.)(mm) | Total Weight Approx. (kg/km) |

|---|---|---|---|---|

2×0.5 | 0.6 | 0.7 | 5.8 | 35 |

2×0.75 | 0.6 | 0.8 | 6.4 | 44 |

2×1 | 0.6 | 0.8 | 6.7 | 51 |

2×1.5 | 0.7 | 0.9 | 7.7 | 70 |

2×2.5 | 0.8 | 1.0 | 9.2 | 104 |

5×0.5 | 0.6 | 0.9 | 7.7 | 73 |

5×0.75 | 0.6 | 0.9 | 8.2 | 88 |

5×1 | 0.6 | 1.0 | 8.9 | 109 |

5×1.5 | 0.7 | 1.0 | 10.0 | 146 |

5×2.5 | 0.8 | 1.2 | 12.0 | 223 |

7×0.5 | 0.6 | 1.0 | 9.2 | 99 |

7×0.75 | 0.6 | 1.0 | 9.9 | 122 |

7×1 | 0.6 | 1.1 | 10.7 | 149 |

7×1.5 | 0.7 | 1.2 | 12.3 | 207 |

7×2.5 | 0.8 | 1.4 | 14.7 | 314 |

No. of Cores & Cross Section (mm2) | Nominal insulation Thickness (mm) | Nominal Sheath Thickness (mm) | Overall Dia. (Approx.)(mm) | Total Weight Approx. (kg/km) |

|---|---|---|---|---|

12×0.5 | 0.6 | 1.1 | 11.2 | 157 |

12×0.75 | 0.6 | 1.2 | 12.2 | 199 |

12×1 | 0.6 | 1.2 | 13.0 | 238 |

12×1.5 | 0.7 | 1.4 | 15.0 | 335 |

12×2.5 | 0.8 | 1.6 | 18.0 | 513 |

19×0.5 | 0.6 | 1.3 | 13.3 | 236 |

19×0.75 | 0.6 | 1.3 | 14.4 | 298 |

19×1 | 0.6 | 1.4 | 15.5 | 363 |

19×1.5 | 0.7 | 1.6 | 17.9 | 513 |

19×2.5 | 0.8 | 1.8 | 21.3 | 779 |

24×0.5 | 0.6 | 1.4 | 15.7 | 302 |

24×0.75 | 0.6 | 1.5 | 17.1 | 384 |

24×1 | 0.6 | 1.6 | 18.4 | 467 |

24×1.5 | 0.7 | 1.8 | 21.2 | 657 |

24×2.5 | 0.8 | 2.1 | 25.4 | 1003 |

No. of Cores & Cross Section (mm2) | Nominal insulation Thickness (mm) | Nominal Sheath Thickness (mm) | Overall Dia. (Approx.)(mm) | Total Weight Approx. (kg/km) |

|---|---|---|---|---|

30×0.5 | 0.6 | 1.5 | 16.7 | 364 |

30×0.75 | 0.6 | 1.6 | 18.3 | 469 |

30×1 | 0.6 | 1.7 | 19.6 | 568 |

30×1.5 | 0.7 | 1.9 | 22.6 | 801 |

30×2.5 | 0.8 | 2.2 | 27.1 | 1227 |

37×0.5 | 0.6 | 1.6 | 18.2 | 236 |

37×0.75 | 0.6 | 1.7 | 19.9 | 570 |

37×1 | 0.6 | 1.8 | 21.3 | 690 |

37×1.5 | 0.7 | 2.0 | 24.5 | 970 |

37×2.5 | 0.8 | 2.4 | 29.6 | 1504 |

48×0.5 | 0.6 | 1.8 | 21.0 | 574 |

48×0.75 | 0.6 | 1.9 | 23.0 | 739 |

48×1 | 0.6 | 2.0 | 24.6 | 893 |

48×1.5 | 0.7 | 2.3 | 28.4 | 1263 |

48×2.5 | 0.8 | 2.7 | 34.2 | 1948 |

No. of Cores & Cross Section (mm2) | Nominal insulation Thickness (mm) | Nominal Sheath Thickness (mm) | Overall Dia. (Approx.)(mm) | Total Weight Approx. (kg/km) |

|---|---|---|---|---|

50×0.5 | 0.6 | 1.8 | 21.1 | 595 |

50×0.75 | 0.6 | 1.9 | 23.0 | 761 |

50×1 | 0.6 | 2.0 | 24.6 | 920 |

50×1.5 | 0.7 | 2.3 | 28.4 | 1302 |

50×2.5 | 0.8 | 2.7 | 34.3 | 2018 |

54×0.5 | 0.6 | 1.8 | 21.6 | 631 |

54×0.75 | 0.6 | 2.0 | 23.8 | 823 |

54×1 | 0.6 | 2.1 | 25.5 | 997 |

54×1.5 | 0.7 | 2.4 | 29.4 | 1409 |

54×2.5 | 0.8 | 2.8 | 35.4 | 2175 |

55×0.5 | 0.6 | 1.8 | 21.6 | 640 |

55×0.75 | 0.6 | 2.0 | 23.8 | 834 |

55×1 | 0.6 | 2.1 | 25.5 | 1012 |

55×1.5 | 0.7 | 2.4 | 29.4 | 1429 |

55×2.5 | 0.8 | 2.8 | 35.4 | 2207 |

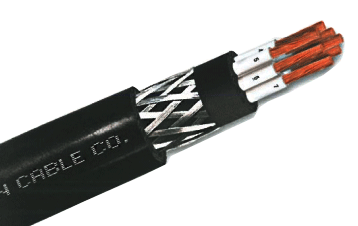

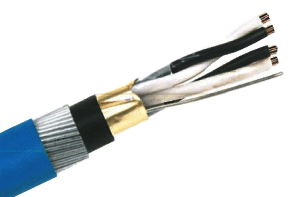

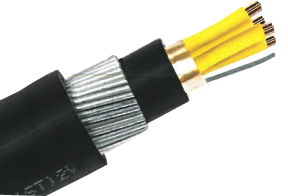

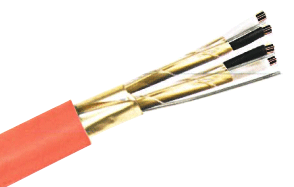

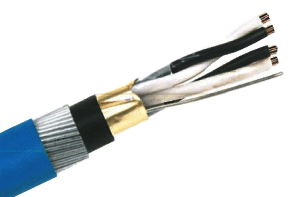

Flexible Screened Cable NYSLYCYO

- Voltage Rate: 300-500 V

Applicable Standard: IEC 60227, IEC 60228

- Code Designation Of Wire According IEC: 60227 IEC 74

Construction:

Conductor: Plain Annealed Copper Wire or Tin Coated Wires(Class 5)

Insulation Type: P.V.C/D

Inner Sheath Type: P.V.C/ST5

Screen: Braided Copper Wire

Outer Sheath Type: P.V.C/ST9

Maximum Conductor Temperature: 70°C

- Application:

Flexible screened cables are used for medium mechanical stress, but without tensile stress or forced movements in dry wet and moist areas but are not suitable for open air application. These cables are used in measuring and control technics conveyor belts, production lines, air – conditioning, machine tools etc. the cores are numbered in such way that they are still recognizable even after a small part of the outer sheath is removed. special PVC compound ensures good flexibility and IS extensively oil resistant.

No. of Cores & Cross Section (mm2) | Nominal insulation Thickness (mm) | Nominal Inner Layer Dia. (mm) | Armour Wire Dia. (mm) | Nominal Sheath Thickness (mm) | Overall Dia. (Approx.)(mm) | Total Weight Approx. (kg/km) |

|---|---|---|---|---|---|---|

2×0.5 | 0.6 | 0.7 | 0.15 | 0.9 | 8.2 | 88 |

2×0.75 | 0.6 | 0.7 | 0.15 | 0.9 | 8.6 | 96 |

2×1 | 0.6 | 0.7 | 0.15 | 1.0 | 9.1 | 107 |

2×1.5 | 0.7 | 0.7 | 0.15 | 1.0 | 9.9 | 126 |

2×2.5 | 0.8 | 0.7 | 0.15 | 1.1 | 11.4 | 167 |

5×0.5 | 0.6 | 0.7 | 0.15 | 1.0 | 9.9 | 130 |

5×0.75 | 0.6 | 0.7 | 0.15 | 1.1 | 10.6 | 152 |

5×1 | 0.6 | 0.7 | 0.15 | 1.1 | 11.1 | 170 |

5×1.5 | 0.7 | 0.8 | 0.15 | 1.2 | 12.6 | 226 |

5×2.5 | 0.8 | 0.8 | 0.2 | 1.4 | 14.8 | 321 |

7×0.5 | 0.6 | 0.7 | 0.15 | 1.1 | 11.4 | 161 |

7×0.75 | 0.6 | 0.8 | 0.15 | 1.2 | 12.5 | 201 |

7×1 | 0.6 | 0.8 | 0.15 | 1.3 | 13.3 | 232 |

7×1.5 | 0.7 | 0.8 | 0.2 | 1.4 | 15.1 | 307 |

7×2.5 | 0.8 | 0.8 | 0.2 | 1.5 | 17.3 | 417 |

No. of Cores & Cross Section (mm2) | Nominal insulation Thickness (mm) | Nominal Inner Layer Dia. (mm) | Armour Wire Dia. (mm) | Nominal Sheath Thickness (mm) | Overall Dia. (Approx.)(mm) | Total Weight Approx. (kg/km) |

|---|---|---|---|---|---|---|

12×0.5 | 0.6 | 0.8 | 0.2 | 1.3 | 14.0 | 251 |

12×0.75 | 0.6 | 0.8 | 0.2 | 1.4 | 15.0 | 298 |

12×1 | 0.6 | 0.8 | 0.2 | 1.4 | 15.8 | 341 |

12×1.5 | 0.7 | 0.8 | 0.2 | 1.6 | 17.8 | 448 |

12×2.5 | 0.8 | 0.9 | 0.2 | 1.8 | 21.0 | 656 |

19×0.5 | 0.6 | 0.8 | 0.2 | 1.5 | 16.1 | 341 |

19×0.75 | 0.6 | 0.8 | 0.2 | 1.5 | 17.2 | 408 |

19×1 | 0.6 | 0.9 | 0.2 | 1.6 | 18.5 | 486 |

19×1.5 | 0.7 | 0.9 | 0.2 | 1.8 | 20.9 | 656 |

19×2.5 | 0.8 | 1.0 | 0.2 | 2.0 | 24.5 | 950 |

24×0.5 | 0.6 | 0.9 | 0.2 | 1.6 | 18.7 | 433 |

24×0.75 | 0.6 | 0.9 | 0.2 | 1.7 | 20.1 | 522 |

24×1 | 0.6 | 0.9 | 0.2 | 1.8 | 21.4 | 612 |

19×1.5 | 0.7 | 0.9 | 0.2 | 1.8 | 20.9 | 656 |

19×2.5 | 0.8 | 1.0 | 0.2 | 2.0 | 24.5 | 950 |

No. of Cores & Cross Section (mm2) | Nominal insulation Thickness (mm) | Nominal Inner Layer Dia. (mm) | Armour Wire Dia. (mm) | Nominal Sheath Thickness (mm) | Overall Dia. (Approx.)(mm) | Total Weight Approx. (kg/km) |

|---|---|---|---|---|---|---|

24×0.5 | 0.6 | 0.9 | 0.2 | 1.6 | 18.7 | 433 |

24×0.75 | 0.6 | 0.9 | 0.2 | 1.7 | 20.1 | 522 |

24×1 | 0.6 | 0.9 | 0.2 | 1.8 | 21.4 | 612 |

24×1.5 | 0.7 | 1.0 | 0.2 | 2.0 | 24.4 | 828 |

24×2.5 | 0.8 | 1.0 | 0.25 | 2.3 | 28.8 | 1212 |

30×0.5 | 0.6 | 0.9 | 0.2 | 1.7 | 19.7 | 501 |

30×0.75 | 0.6 | 0.9 | 0.2 | 1.8 | 21.3 | 614 |

30×1 | 0.6 | 0.9 | 0.2 | 1.9 | 22.6 | 719 |

30×1.5 | 0.7 | 1.0 | 0.25 | 2.1 | 26.0 | 994 |

30×2.5 | 0.8 | 1.1 | 0.25 | 2.5 | 30.9 | 1532 |

37×0.5 | 0.6 | 0.9 | 0.2 | 1.8 | 21.2 | 588 |

37×0.75 | 0.6 | 0.9 | 0.2 | 1.9 | 22.9 | 723 |

37×1 | 0.6 | 1.0 | 0.2 | 2.0 | 24.5 | 861 |

37×1.5 | 0.8 | 1.1 | 0.25 | 2.3 | 28.1 | 1187 |

37×2.5 | 0.8 | 1.1 | 0.25 | 2.6 | 33.2 | 1810 |

No. of Cores & Cross Section (mm2) | Nominal insulation Thickness (mm) | Nominal Inner Layer Dia. (mm) | Armour Wire Dia. (mm) | Nominal Sheath Thickness (mm) | Overall Dia. (Approx.)(mm) | Total Weight Approx. (kg/km) |

|---|---|---|---|---|---|---|

24×0.5 | 0.6 | 0.9 | 0.2 | 2.0 | 24.0 | 733 |

48×0.75 | 0.6 | 1.0 | 0.2 | 2.0 | 26.6 | 946 |

48×1 | 0.6 | 1.0 | 0.25 | 2.3 | 28.2 | 1110 |

48×1.5 | 0.7 | 1.1 | 0.25 | 2.6 | 32.2 | 1577 |

48×2.5 | 0.8 | 1.2 | 0.3 | 3.0 | 38.4 | 2347 |

50×0.5 | 0.6 | 0.9 | 0.2 | 2.0 | 24.1 | 755 |

50×0.75 | 0.6 | 1.0 | 0.25 | 2.2 | 26.6 | 968 |

50×1 | 0.6 | 1.0 | 0.25 | 2.3 | 28.2 | 1137 |

50×1.5 | 0.7 | 1.1 | 0.25 | 2.6 | 32.2 | 1616 |

50×2.5 | 0.8 | 1.2 | 0.3 | 3.0 | 38.5 | 2418 |

54×0.5 | 0.6 | 1.0 | 0.2 | 2.1 | 25.0 | 816 |

54×0.75 | 0.6 | 1.0 | 0.25 | 2.2 | 27.2 | 1023 |

54×1 | 0.6 | 1.0 | 0.25 | 2.3 | 28.9 | 1207 |

54×1.5 | 0.7 | 1.1 | 0.25 | 2.6 | 33.0 | 1715 |

54×2.5 | 0.8 | 1.2 | 0.3 | 3.1 | 39.6 | 2582 |

55×0.5 | 0.6 | 1.0 | 0.2 | 2.1 | 25.0 | 824 |

55×0.75 | 0.6 | 1.0 | 0.25 | 2.2 | 27.2 | 1034 |

55×1 | 0.6 | 1.0 | 0.25 | 2.3 | 28.9 | 1221 |

55×1.5 | 0.7 | 1.1 | 0.25 | 2.6 | 33.0 | 1735 |

55×2.5 | 0.8 | 1.2 | 0.3 | 3.1 | 39.6 | 2615 |

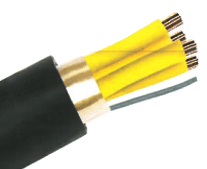

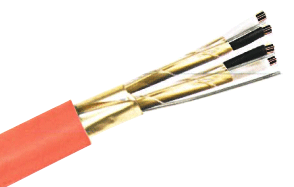

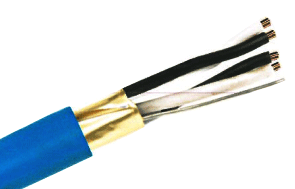

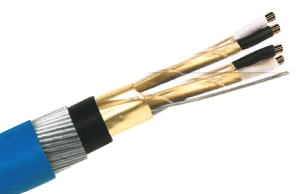

Multicore Screened Instrument Cables MSR- Y (ST) Y

- Voltage Rate: 300-500 V

Applicable Standard: BS 5308

- Code Designation Of Wire According IEC: 60227 IEC 74

Construction:

:Construction

Plain Annealed Copper Conductor – Class (1,2,5)

Insulation Type: P.V.C

Screen Over Laying up Cores: Drain Wire + Aluminum Foil

Sheath: P.V.C

Maximum Conductor Temperature: 70°C

- Application:

Transmission of Analog and Digital Signals in Instrumentation System, the cables are suitable to be laid indoors and outdoors, on the trays or in pipes.

No. of Cores & Cross Section (mm2) | Nominal insulation Thickness (mm) | Nominal Sheath Thickness. (mm) | Overall Dia. (Approx.)(mm) | Total Weight Approx. (kg/km) |

|---|---|---|---|---|

2×0.5 | 0.6 | 0.8 | 6.2 | 44.6 |

3×0.5 | 0.6 | 0.8 | 6.5 | 54.8 |

4×0.5 | 0.6 | 0.8 | 7.1 | 65.7 |

5×0.5 | 0.6 | 0.9 | 7.4 | 78.4 |

6×0.5 | 0.6 | 0.9 | 8.5 | 92.1 |

7×0.5 | 0.6 | 1.1 | 8.9 | 108.6 |

8×0.5 | 0.6 | 1.1 | 10.3 | 125.1 |

9×0.5 | 0.6 | 1.1 | 11.0 | 137.9 |

10×0.5 | 0.6 | 1.1 | 11.0 | 146.4 |

11×0.5 | 0.6 | 1.2 | 11.2 | 160.0 |

12×0.5 | 0.6 | 1.2 | 11.5 | 170.7 |

13×0.5 | 0.6 | 1.2 | 12.0 | 182.5 |

14×0.5 | 0.6 | 1.2 | 12.0 | 191.1 |

15×0.5 | 0.6 | 1.2 | 12.6 | 203.6 |

20×0.5 | 0.6 | 1.2 | 14.0 | 256.3 |

25×0.5 | 0.6 | 1.3 | 15.6 | 315.3 |

30×0.5 | 0.6 | 1.3 | 16.4 | 364.0 |

35×0.5 | 0.6 | 1.3 | 17.7 | 415.4 |

40×0.5 | 0.6 | 1.3 | 18.4 | 463.0 |

45×0.5 | 0.6 | 1.5 | 20.2 | 533.7 |

50×0.5 | 0.6 | 1.5 | 20.5 | 579.2 |

55×0.5 | 0.6 | 1.5 | 21.1 | 626.2 |

No. of Cores & Cross Section (mm2) | Nominal insulation Thickness (mm) | Nominal Sheath Thickness. (mm) | Overall Dia. (Approx.)(mm) | Total Weight Approx. (kg/km) |

|---|---|---|---|---|

2×1 | 0.6 | 0.8 | 7.0 | 59.3 |

3×1 | 0.6 | 0.9 | 7.6 | 78.6 |

4×1 | 0.6 | 0.9 | 8.2 | 95.9 |

5×1 | 0.6 | 1.1 | 8.8 | 118.8 |

6×1 | 0.6 | 1.1 | 10.1 | 140.2 |

7×1 | 0.6 | 1.2 | 10.2 | 159.0 |

8×1 | 0.6 | 1.2 | 11.9 | 183.5 |

9×1 | 0.6 | 1.2 | 12.7 | 202.9 |

10×1 | 0.6 | 1.2 | 12.7 | 217.0 |

11×1 | 0.6 | 1.3 | 12.9 | 237.0 |

12×1 | 0.6 | 1.3 | 13.3 | 253.9 |

13×1 | 0.6 | 1.3 | 14.0 | 272.2 |

14×1 | 0.6 | 1.3 | 14.0 | 286.3 |

15×1 | 0.6 | 1.3 | 14.7 | 305.4 |

20×1 | 0.6 | 1.3 | 16.2 | 388.7 |

25×1 | 0.6 | 1.5 | 18.3 | 487.4 |

30×1 | 0.6 | 1.5 | 19.3 | 566.1 |

35×1 | 0.6 | 1.5 | 20.8 | 648.3 |

40×1 | 0.6 | 1.5 | 21.6 | 725.5 |

45×1 | 0.6 | 1.7 | 23.7 | 830.6 |

50×1 | 0.6 | 1.7 | 24.1 | 904.9 |

55×1 | 0.6 | 1.7 | 24.7 | 981.3 |

No. of Cores & Cross Section (mm2) | Nominal insulation Thickness (mm) | Nominal Sheath Thickness. (mm) | Overall Dia. (Approx.)(mm) | Total Weight Approx. (kg/km) |

|---|---|---|---|---|

2×1.5 | 0.6 | 0.8 | 7.6 | 72.6 |

3×1.5 | 0.6 | 1.0 | 8.4 | 101.6 |

4×1.5 | 0.6 | 0.9 | 8.9 | 120.8 |

5×1.5 | 0.6 | 1.1 | 9.6 | 149.9 |

6×1.5 | 0.6 | 1.1 | 10.9 | 177.5 |

7×1.5 | 0.6 | 1.2 | 11.1 | 202.1 |

8×1.5 | 0.6 | 1.3 | 13.2 | 239.0 |

9×1.5 | 0.6 | 1.4 | 14.3 | 271.4 |

10×1.5 | 0.6 | 1.4 | 14.3 | 290.9 |

11×1.5 | 0.6 | 1.3 | 14.1 | 303.9 |

12×1.5 | 0.6 | 1.4 | 14.8 | 333.1 |

13×1.5 | 0.6 | 1.3 | 15.3 | 350.5 |

14×1.5 | 0.6 | 1.5 | 15.7 | 384.1 |

15×1.5 | 0.6 | 1.3 | 16.1 | 394.1 |

20×1.5 | 0.6 | 1.3 | 17.8 | 506.5 |

25×1.5 | 0.6 | 1.5 | 20.1 | 635.0 |

30×1.5 | 0.6 | 1.5 | 21.3 | 741.3 |

35×1.5 | 0.6 | 1.5 | 22.9 | 851.6 |

40×1.5 | 0.6 | 1.5 | 23.8 | 956.2 |

45×1 | 0.6 | 1.7 | 26.1 | 1091.8 |

50×1.5 | 0.6 | 1.7 | 26.5 | 1193.2 |

55×1.5 | 0.6 | 1.7 | 27.3 | 1296.9 |

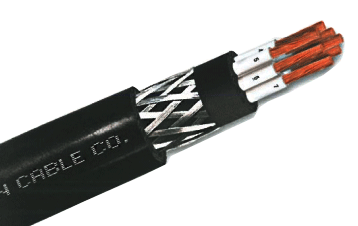

Multi Core Screened Armored Instrument Cables MSR-Y (ST) YRY

- Voltage Rate: 300-500 V

Applicable Standard: BS 5308

Construction:

Plain Annealed Copper Conductor – Class (1,2,5)

Insulation Type: P.V.C

Screen Over Laying up Cores: Drain Wire + Aluminum Foil

Inner Sheath: P.V.C

Armor: Galvanized Steel Wire

Sheath: P.V.C

- Application:

Transmission of Analog and Digital Signals in Instrumentation System, the cables are suitable to be laid indoors and outdoors, on cable trays or in pipes or in earth.

No. of Cores & Cross Section (mm2) | Nominal insulation Thickness (mm) | Nominal Inner Layer Thickness (mm) | Armour Wire Dia. (mm) | Nominal Sheath Thickness. (mm) | Overall Dia. (Approx.)(mm) | Total Weight Approx. (kg/km) |

|---|---|---|---|---|---|---|

2×0.5 | 0.6 | 0.8 | 0.9 | 1.3 | 10.6 | 44.6 |

3×0.5 | 0.6 | 0.8 | 0.9 | 1.3 | 10.9 | 238.2 |

4×0.5 | 0.6 | 0.8 | 0.9 | 1.3 | 11.5 | 262.5 |

5×0.5 | 0.6 | 0.9 | 0.9 | 1.4 | 12.0 | 287.8 |

6×0.5 | 0.6 | 0.9 | 0.9 | 1.4 | 13.1 | 323.4 |

7×0.5 | 0.6 | 1.1 | 0.9 | 1.5 | 13.7 | 358.8 |

8×0.5 | 0.6 | 1.1 | 1.25 | 1.5 | 15.8 | 495.9 |

9×0.5 | 0.6 | 1.1 | 1.25 | 1.5 | 16.5 | 523.2 |

10×0.5 | 0.6 | 1.1 | 1.25 | 1.5 | 16.5 | 531.8 |

11×0.5 | 0.6 | 1.2 | 1.25 | 1.6 | 16.9 | 564.2 |

12×0.5 | 0.6 | 1.2 | 1.25 | 1.6 | 17.2 | 587.1 |

13×0.5 | 0.6 | 1.2 | 1.25 | 1.6 | 17.7 | 612.4 |

14×0.5 | 0.6 | 1.2 | 1.25 | 1.6 | 17.7 | 621.0 |

15×0.5 | 0.6 | 1.2 | 1.25 | 1.6 | 18.3 | 647.7 |

20×0.5 | 0.6 | 1.2 | 1.25 | 1.6 | 19.7 | 739.4 |

25×0.5 | 0.6 | 1.3 | 1.6 | 1.7 | 22.2 | 985.5 |

30×0.5 | 0.6 | 1.3 | 1.6 | 1.7 | 23.0 | 1072.9 |

35×0.5 | 0.6 | 1.3 | 1.6 | 1.7 | 24.3 | 1165.8 |

40×0.5 | 0.6 | 1.3 | 1.6 | 1.7 | 25.0 | 1234.7 |

45×0.5 | 0.6 | 1.5 | 1.6 | 1.9 | 27.2 | 1408.0 |

50×0.5 | 0.6 | 1.5 | 1.6 | 1.9 | 27.5 | 1456.5 |

55×0.5 | 0.6 | 1.5 | 1.6 | 1.9 | 28.1 | 1524.1 |

No. of Cores & Cross Section (mm2) | Nominal insulation Thickness (mm) | Nominal Inner Layer Thickness (mm) | Armour Wire Dia. (mm) | Nominal Sheath Thickness. (mm) | Overall Dia. (Approx.)(mm) | Total Weight Approx. (kg/km) |

|---|---|---|---|---|---|---|

2×0.75 | 0.6 | 0.8 | 0.9 | 1.3 | 11.0 | 236.1 |

3×0.75 | 0.6 | 0.8 | 0.9 | 1.3 | 11.4 | 256.4 |

4×0.75 | 0.6 | 0.8 | 0.9 | 1.4 | 12.2 | 289.6 |

5×0.75 | 0.6 | 0.9 | 0.9 | 1.4 | 12.6 | 318.1 |

6×0.75 | 0.6 | 0.9 | 0.9 | 1.4 | 13.7 | 357.6 |

7×0.75 | 0.6 | 1.1 | 0.9 | 1.5 | 14.3 | 396.6 |

8×0.75 | 0.6 | 1.1 | 1.25 | 1.5 | 16.5 | 547.7 |

9×0.75 | 0.6 | 1.1 | 1.25 | 1.5 | 17.3 | 578.8 |

10×0.75 | 0.6 | 1.1 | 1.25 | 1.5 | 17.3 | 590.2 |

11×0.75 | 0.6 | 1.2 | 1.25 | 1.6 | 17.7 | 626.2 |

12×0.75 | 0.6 | 1.2 | 1.25 | 1.6 | 18.1 | 652.4 |

13×0.75 | 0.6 | 1.2 | 1.25 | 1.6 | 18.7 | 681.4 |

14×0.75 | 0.6 | 1.2 | 1.25 | 1.6 | 18.7 | 692.8 |

15×0.75 | 0.6 | 1.2 | 1.25 | 1.6 | 19.3 | 732.8 |

20×0.75 | 0.6 | 1.2 | 1.6 | 1.6 | 21.5 | 960.8 |

25×0.75 | 0.6 | 1.3 | 1.6 | 1.8 | 23.6 | 1133.4 |

30×0.75 | 0.6 | 1.3 | 1.6 | 1.8 | 24.6 | 1220.7 |

35×0.75 | 0.6 | 1.3 | 1.6 | 1.8 | 26.0 | 1346.2 |

40×0.75 | 0.6 | 1.3 | 1.6 | 1.8 | 26.7 | 1430.6 |

45×0.75 | 0.6 | 1.5 | 1.6 | 2.0 | 29.07 | 1624.2 |

50×0.75 | 0.6 | 1.5 | 1.6 | 2.0 | 29.4 | 1687.5 |

55×0.75 | 0.6 | 1.5 | 1.6 | 2.0 | 30.0 | 1786.6 |

No. of Cores & Cross Section (mm2) | Nominal insulation Thickness (mm) | Nominal Inner Layer Thickness (mm) | Armour Wire Dia. (mm) | Nominal Sheath Thickness. (mm) | Overall Dia. (Approx.)(mm) | Total Weight Approx. (kg/km) |

|---|---|---|---|---|---|---|

2×1 | 0.6 | 0.8 | 0.9 | 1.4 | 11.6 | 255.6 |

3×1 | 0.6 | 0.9 | 0.9 | 1.4 | 12.2 | 288.9 |

4×1 | 0.6 | 0.9 | 0.9 | 1.4 | 12.8 | 320.5 |

5×1 | 0.6 | 1.1 | 0.9 | 1.4 | 13.4 | 357.3 |

6×1 | 0.6 | 1.1 | 0.9 | 1.4 | 14.6 | 406.9 |

7×1 | 0.6 | 1.2 | 1.25 | 1.6 | 15.9 | 536.8 |

8×1 | 0.6 | 1.2 | 1.25 | 1.6 | 17.6 | 612.3 |

9×1 | 0.6 | 1.2 | 1.25 | 1.6 | 18.4 | 657.4 |

10×1 | 0.6 | 1.2 | 1.25 | 1.6 | 18.4 | 671.6 |

11×1 | 0.6 | 1.3 | 1.25 | 1.7 | 18.8 | 701.6 |

12×1 | 0.6 | 1.3 | 1.25 | 1.7 | 19.2 | 731.3 |

13×1 | 0.6 | 1.3 | 1.25 | 1.7 | 19.9 | 764.1 |

14×1 | 0.6 | 1.3 | 1.25 | 1.7 | 19.9 | 778.3 |

15×1 | 0.6 | 1.3 | 1.25 | 1.7 | 20.6 | 822.4 |

20×1 | 0.6 | 1.3 | 1.6 | 1.7 | 22.8 | 1080.1 |

25×1 | 0.6 | 1.5 | 1.6 | 1.9 | 25.3 | 1281.7 |

30×1 | 0.6 | 1.5 | 1.6 | 1.9 | 26.3 | 1401.2 |

35×1 | 0.6 | 1.5 | 1.6 | 1.9 | 27.8 | 1544.1 |

40×1 | 0.6 | 1.5 | 1.6 | 1.9 | 28.6 | 1644.3 |

45×1 | 0.6 | 1.7 | 1.6 | 2.1 | 31.1 | 1859.4 |

50×1 | 0.6 | 1.7 | 1.6 | 2.1 | 31.5 | 1953 |

55×1 | 0.6 | 1.7 | 1.6 | 2.1 | 32.1 | 2052.1 |

No. of Cores & Cross Section (mm2) | Nominal insulation Thickness (mm) | Nominal Inner Layer Thickness (mm) | Armour Wire Dia. (mm) | Nominal Sheath Thickness. (mm) | Overall Dia. (Approx.)(mm) | Total Weight Approx. (kg/km) |

|---|---|---|---|---|---|---|

2×1.5 | 0.6 | 0.8 | 0.9 | 1.4 | 12.2 | 282.9 |

3×1.5 | 0.6 | 1.0 | 0.9 | 1.4 | 13.0 | 332.5 |

4×1.5 | 0.6 | 0.9 | 0.9 | 1.4 | 13.5 | 365.1 |

5×1.5 | 0.6 | 1.1 | 0.9 | 1.4 | 14.2 | 408.4 |

6×1.5 | 0.6 | 1.1 | 1.25 | 1.4 | 16.2 | 555.3 |

7×1.5 | 0.6 | 1.2 | 1.25 | 1.6 | 16.8 | 606.0 |

8×1.5 | 0.6 | 1.3 | 1.25 | 1.6 | 18.9 | 706.6 |

9×1.5 | 0.6 | 1.4 | 1.25 | 1.6 | 20.0 | 766.9 |

10×1.5 | 0.6 | 1.4 | 1.25 | 1.6 | 20.0 | 786.4 |

11×1.5 | 0.6 | 1.3 | 1.25 | 1.7 | 20.0 | 807.0 |

12×1.5 | 0.6 | 1.4 | 1.25 | 1.7 | 20.7 | 851.0 |

13×1.5 | 0.6 | 1.3 | 1.6 | 1.7 | 21.9 | 1018.4 |

14×1.5 | 0.6 | 1.5 | 1.6 | 1.7 | 22.3 | 1055.1 |

15×1.5 | 0.6 | 1.3 | 1.6 | 1.7 | 22.7 | 1085.0 |

20×1.5 | 0.6 | 1.3 | 1.6 | 1.7 | 24.4 | 1258.3 |

25×1.5 | 0.6 | 1.5 | 1.6 | 1.9 | 27.1 | 1508.7 |

30×1.5 | 0.6 | 1.5 | 1.6 | 1.9 | 28.3 | 1656.9 |

35×1.5 | 0.6 | 1.5 | 1.6 | 1.9 | 29.9 | 1829.5 |

40×1.5 | 0.6 | 1.5 | 1.6 | 1.9 | 30.8 | 1958.0 |

45×1.5 | 0.6 | 1.7 | 2.0 | 2.1 | 34.3 | 2449.0 |

50×1.5 | 0.6 | 1.7 | 2.0 | 2.1 | 34.7 | 2579.7 |

55×1.5 | 0.6 | 1.7 | 2.0 | 2.1 | 35.5 | 2715.3 |

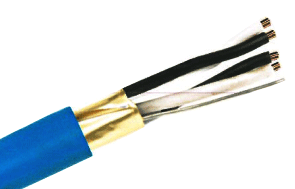

Overall Screened Instrument Cables MSR - Y (ST) Y

- Voltage Rate: 300-500 V

Applicable Standard: BS 5308

Construction:

Plain Annealed Copper Conductor – Class (1,2,5)

Insulation Type: P.V.C

Twisted Pair

Screen Over Laying up Pairs: Drain Wire + Aluminum Foil

Sheath: P.V.C

- Application:

Transmission of Analog and Digital Signals in Instrumentation System, the cables are suitable to be laid indoors and outdoors, on the trays or in pipes.

No. of Cores & Cross Section (mm2) | Nominal insulation Thickness (mm) | Nominal Sheath Thickness. (mm) | Overall Dia. (Approx.)(mm) | Total Weight Approx. (kg/km) |

|---|---|---|---|---|

1×2×0.5 | 0.6 | 0.8 | 6.2 | 45 |

2×2×0.5 | 0.6 | 1.1 | 8.5 | 80 |

3×2×0.5 | 0.6 | 1.2 | 9.9 | 109 |

4×2×0.5 | 0.6 | 1.2 | 11.0 | 133 |

5×2×0.5 | 0.6 | 1.2 | 12.0 | 157 |

6×2×0.5 | 0.6 | 1.3 | 13.1 | 185 |

7×2×0.5 | 0.6 | 1.3 | 13.9 | 208 |

8×2×0.5 | 0.6 | 1.3 | 14.5 | 229 |

9×2×0.5 | 0.6 | 1.3 | 15.4 | 252 |

10×2×0.5 | 0.6 | 1.3 | 16.0 | 273 |

11×2×0.5 | 0.6 | 1.5 | 17.0 | 310 |

12×2×0.5 | 0.6 | 1.5 | 17.7 | 332 |

13×2×0.5 | 0.6 | 1.5 | 18.1 | 352 |

14×2×0.5 | 0.6 | 1.5 | 18.7 | 374 |

15×2×0.5 | 0.6 | 1.5 | 19.3 | 369 |

20×2×0.5 | 0.6 | 1.5 | 21.6 | 502 |

25×2×0.5 | 0.6 | 1.7 | 24.4 | 628 |

30×2×0.5 | 0.6 | 1.7 | 26.2 | 730 |

35×2×0.5 | 0.6 | 2.2 | 28.9 | 895 |

40×2×0.5 | 0.6 | 2.2 | 30.6 | 999 |

45×2×0.5 | 0.6 | 2.2 | 32.3 | 1103 |

50×2×0.5 | 0.6 | 2.2 | 33.8 | 1205 |

No. of Cores & Cross Section (mm2) | Nominal insulation Thickness (mm) | Nominal Sheath Thickness. (mm) | Overall Dia. (Approx.)(mm) | Total Weight Approx. (kg/km) |

|---|---|---|---|---|

1×2×0.75 | 0.6 | 0.8 | 6.6 | 52 |

2×2×0.75 | 0.6 | 1.1 | 9.0 | 95 |

3×2×0.75 | 0.6 | 1.2 | 10.6 | 131 |

4×2×0.75 | 0.6 | 1.2 | 11.8 | 161 |

5×2×0.75 | 0.6 | 1.2 | 12.9 | 191 |

6×2×0.75 | 0.6 | 1.3 | 14.1 | 226 |

7×2×0.75 | 0.6 | 1.3 | 15.0 | 255 |

8×2×0.75 | 0.6 | 1.3 | 15.7 | 282 |

9×2×0.75 | 0.6 | 1.3 | 16.6 | 311 |

10×2×0.75 | 0.6 | 1.3 | 17.3 | 339 |

11×2×0.75 | 0.6 | 1.5 | 18.4 | 383 |

12×2×0.75 | 0.6 | 1.5 | 19.1 | 411 |

13×2×0.75 | 0.6 | 1.5 | 19.5 | 437 |

14×2×0.75 | 0.6 | 1.5 | 20.2 | 465 |

15×2×0.75 | 0.6 | 1.5 | 20.9 | 493 |

20×2×0.75 | 0.6 | 1.7 | 23.9 | 651 |

25×2×0.75 | 0.6 | 2.0 | 27.0 | 824 |

30×2×0.75 | 0.6 | 2.0 | 29.1 | 959 |

35×2×0.75 | 0.6 | 2.2 | 31.3 | 1120 |

40×2×0.75 | 0.6 | 2.2 | 33.2 | 1254 |

45×2×0.75 | 0.6 | 2.2 | 35.0 | 1388 |

50×2×0.75 | 0.6 | 2.2 | 36.7 | 1520 |

No. of Cores & Cross Section (mm2) | Nominal insulation Thickness (mm) | Nominal Sheath Thickness. (mm) | Overall Dia. (Approx.)(mm) | Total Weight Approx. (kg/km) |

|---|---|---|---|---|

1×2×1 | 0.6 | 0.8 | 7.0 | 59 |

2×2×1 | 0.6 | 1.2 | 9.7 | 113 |

3×2×1 | 0.6 | 1.3 | 11.4 | 156 |

4×2×1 | 0.6 | 1.3 | 12.7 | 193 |

5×2×1 | 0.6 | 1.3 | 13.9 | 230 |

6×2×1 | 0.6 | 1.5 | 15.3 | 278 |

7×2×1 | 0.6 | 1.5 | 16.3 | 314 |

8×2×1 | 0.6 | 1.5 | 17.1 | 348 |

9×2×1 | 0.6 | 1.5 | 18.1 | 384 |

10×2×1 | 0.6 | 1.5 | 18.8 | 418 |

11×2×1 | 0.6 | 1.7 | 20.0 | 470 |

12×2×1 | 0.6 | 1.7 | 20.7 | 505 |

13×2×1 | 0.6 | 1.7 | 21.2 | 537 |

14×2×1 | 0.6 | 1.7 | 21.9 | 572 |

15×2×1 | 0.6 | 1.7 | 22.7 | 607 |

20×2×1 | 0.6 | 1.7 | 25.4 | 775 |

25×2×1 | 0.6 | 2.0 | 28.8 | 979 |

30×2×1 | 0.6 | 2.0 | 31.0 | 1143 |

35×2×1 | 0.6 | 2.2 | 33.4 | 1335 |

40×2×1 | 0.6 | 2.2 | 35.4 | 1498 |

45×2×1 | 0.6 | 2.2 | 37.4 | 1662 |

50×2×1 | 0.6 | 2.2 | 39.1 | 1822 |

No. of Cores & Cross Section (mm2) | Nominal insulation Thickness (mm) | Nominal Sheath Thickness. (mm) | Overall Dia. (Approx.)(mm) | Total Weight Approx. (kg/km) |

|---|---|---|---|---|

1×2×1.5 | 0.6 | 0.8 | 7.6 | 73 |

2×2×1.5 | 0.6 | 1.2 | 10.6 | 140 |

3×2×1.5 | 0.6 | 1.3 | 12.5 | 195 |

4×2×1.5 | 0.6 | 1.3 | 13.9 | 244 |

5×2×1.5 | 0.6 | 1.3 | 15.2 | 292 |

6×2×1.5 | 0.6 | 1.5 | 16.8 | 353 |

7×2×1.5 | 0.6 | 1.5 | 17.9 | 401 |

8×2×1.5 | 0.6 | 1.5 | 18.7 | 446 |

9×2×1.5 | 0.6 | 1.5 | 19.8 | 494 |

10×2×1.5 | 0.6 | 1.5 | 20.7 | 539 |

11×2×1.5 | 0.6 | 1.7 | 21.9 | 604 |

12×2×1.5 | 0.6 | 1.7 | 22.7 | 650 |

13×2×1.5 | 0.6 | 1.7 | 23.3 | 694 |

14×2×1.5 | 0.6 | 1.7 | 24.1 | 740 |

15×2×1.5 | 0.6 | 1.7 | 25.0 | 786 |

20×2×1.5 | 0.6 | 1.7 | 28.0 | 1011 |

25×2×1.5 | 0.6 | 2.0 | 31.7 | 1276 |

30×2×1.5 | 0.6 | 2.0 | 34.2 | 1496 |

35×2×1.5 | 0.6 | 2.2 | 36.9 | 1747 |

40×2×1.5 | 0.6 | 2.2 | 39.1 | 1966 |

45×2×1.5 | 0.6 | 2.2 | 41.3 | 2186 |

50×2×1.5 | 0.6 | 2.2 | 43.3 | 2402 |

No. of Cores & Cross Section (mm2) | Nominal insulation Thickness (mm) | Nominal Sheath Thickness. (mm) | Overall Dia. (Approx.)(mm) | Total Weight Approx. (kg/km) |

|---|---|---|---|---|

1×3×0.5 | 0.6 | 1.2 | 7.3 | 67 |

2×3×0.5 | 0.6 | 1.3 | 12.0 | 127 |

3×3×0.5 | 0.6 | 1.4 | 13.0 | 163 |

4×3×0.5 | 0.6 | 1.4 | 14.2 | 197 |

5×3×0.5 | 0.6 | 1.4 | 15.4 | 232 |

6×3×0.5 | 0.6 | 1.5 | 17.0 | 275 |

7×3×0.5 | 0.6 | 1.5 | 17.0 | 301 |

8×3×0.5 | 0.6 | 1.6 | 20.2 | 359 |

9×3×0.5 | 0.6 | 1.6 | 21.7 | 397 |

10×3×0.5 | 0.6 | 1.6 | 21.7 | 423 |

11×3×0.5 | 0.6 | 1.6 | 21.7 | 448 |

12×3×0.5 | 0.6 | 1.7 | 22.6 | 490 |

13×3×0.5 | 0.6 | 1.7 | 23.8 | 526 |

14×3×0.5 | 0.6 | 1.7 | 23.8 | 551 |

15×3×0.5 | 0.6 | 1.8 | 25.3 | 600 |

25×3×0.5 | 0.6 | 2.0 | 31.6 | 943 |

30×3×0.5 | 0.6 | 2.0 | 33.5 | 1090 |

35×3×0.5 | 0.6 | 2.1 | 36.3 | 1262 |

40×3×0.5 | 0.6 | 2.2 | 38.0 | 1423 |

45×3×0.5 | 0.6 | 2.3 | 41.3 | 1604 |

50×3×0.5 | 0.6 | 2.3 | 41.9 | 1740 |

No. of Cores & Cross Section (mm2) | Nominal insulation Thickness (mm) | Nominal Sheath Thickness. (mm) | Overall Dia. (Approx.)(mm) | Total Weight Approx. (kg/km) |

|---|---|---|---|---|

1×3×0.75 | 0.6 | 1.2 | 7.8 | 79 |

2×3×0.75 | 0.6 | 1.4 | 13.2 | 156 |

3×3×0.75 | 0.6 | 1.4 | 14.0 | 196 |

4×3×0.75 | 0.6 | 1.4 | 15.2 | 239 |

5×3×0.75 | 0.6 | 1.5 | 16.8 | 291 |

6×3×0.75 | 0.6 | 1.5 | 17.0 | 275 |

7×3×0.75 | 0.6 | 1.5 | 18.3 | 371 |

8×3×0.75 | 0.6 | 1.7 | 22.0 | 450 |

9×3×0.75 | 0.6 | 1.7 | 23.7 | 499 |

10×3×0.75 | 0.6 | 1.7 | 23.7 | 533 |

11×3×0.75 | 0.6 | 1.7 | 23.7 | 567 |

12×3×0.75 | 0.6 | 1.7 | 24.5 | 608 |

13×3×0.75 | 0.6 | 1.8 | 26.0 | 665 |

14×3×0.75 | 0.6 | 1.8 | 26.0 | 699 |

15×3×0.75 | 0.6 | 1.8 | 27.4 | 746 |

20×3×0.75 | 0.6 | 1.9 | 30.8 | 964 |

25×3×0.75 | 0.6 | 2.1 | 34.5 | 1198 |

30×3×0.75 | 0.6 | 2.1 | 36.6 | 1391 |

35×3×0.75 | 0.6 | 2.2 | 39.7 | 1611 |

40×3×0.75 | 0.6 | 2.3 | 41.5 | 1818 |

45×3×0.75 | 0.6 | 2.4 | 45.1 | 2048 |

50×3×0.75 | 0.6 | 2.4 | 45.8 | 2228 |

No. of Cores & Cross Section (mm2) | Nominal insulation Thickness (mm) | Nominal Sheath Thickness. (mm) | Overall Dia. (Approx.)(mm) | Total Weight Approx. (kg/km) |

|---|---|---|---|---|

1×3×1 | 0.6 | 1.2 | 7.8 | 79 |

2×3×1 | 0.6 | 1.4 | 13.9 | 178 |

3×3×1 | 0.6 | 1.4 | 14.8 | 227 |

4×3×1 | 0.6 | 1.5 | 16.4 | 287 |

5×3×1 | 0.6 | 1.5 | 17.9 | 340 |

6×3×1 | 0.6 | 1.6 | 19.7 | 404 |

7×3×1 | 0.6 | 1.6 | 19.7 | 447 |

8×3×1 | 0.6 | 1.7 | 23.5 | 528 |

9×3×1 | 0.6 | 1.8 | 25.5 | 598 |

10×3×1 | 0.6 | 1.8 | 25.5 | 640 |

11×3×1 | 0.6 | 1.8 | 25.5 | 683 |

12×3×1 | 0.6 | 1.8 | 26.3 | 733 |

13×3×1 | 0.6 | 1.8 | 27.7 | 788 |

14×3×1 | 0.6 | 1.8 | 27.7 | 830 |

15×3×1 | 0.6 | 1.9 | 29.5 | 900 |

20×3×1 | 0.6 | 2.0 | 33.0 | 1164 |

25×3×1 | 0.6 | 2.1 | 36.8 | 1429 |

30×3×1 | 0.6 | 2.2 | 39.3 | 1682 |

35×3×1 | 0.6 | 2.3 | 42.6 | 1949 |

40×3×1 | 0.6 | 2.4 | 44.6 | 2201 |

45×3×1 | 0.6 | 2.5 | 48.4 | 2479 |

50×3×1 | 0.6 | 2.5 | 49.2 | 2701 |

No. of Cores & Cross Section (mm2) | Nominal insulation Thickness (mm) | Nominal Sheath Thickness. (mm) | Overall Dia. (Approx.)(mm) | Total Weight Approx. (kg/km) |

|---|---|---|---|---|

1×3×1.5 | 0.6 | 1.2 | 8.82 | 109 |

2×3×1.5 | 0.6 | 1.4 | 15.2 | 219 |

3×3×1.5 | 0.6 | 1.5 | 16.4 | 292 |

4×3×1.5 | 0.6 | 1.5 | 18.0 | 362 |

5×3×1.5 | 0.6 | 1.6 | 19.8 | 443 |

6×3×1.5 | 0.6 | 1.6 | 21.7 | 516 |

7×3×1.5 | 0.6 | 1.6 | 21.7 | 574 |

8×3×1.5 | 0.6 | 1.8 | 26.0 | 689 |

9×3×1.5 | 0.6 | 1.9 | 28.3 | 778 |

10×3×1.5 | 0.6 | 1.9 | 28.3 | 837 |

11×3×1.5 | 0.6 | 1.9 | 28.3 | 895 |

12×3×1.5 | 0.6 | 1.9 | 29.2 | 963 |

13×3×1.5 | 0.6 | 1.9 | 30.8 | 1036 |

14×3×1.5 | 0.6 | 1.9 | 30.8 | 1094 |

15×3×1.5 | 0.6 | 2.0 | 32.7 | 1184 |

20×3×1.5 | 0.6 | 2.1 | 36.7 | 1536 |

25×3×1.5 | 0.6 | 2.3 | 41.1 | 1908 |

30×3×1.5 | 0.6 | 2.4 | 43.8 | 2248 |

35×3×1.5 | 0.6 | 2.5 | 47.6 | 2604 |

40×3×1.5 | 0.6 | 2.6 | 49.7 | 2944 |

45×3×1.5 | 0.6 | 2.7 | 54.0 | 3313 |

50×3×1.5 | 0.6 | 2.7 | 54.9 | 3617 |

Multi-Pair Individual Screened Instrument Cables MSR - Y (ST) Y -PIMF

- Voltage Rate: 300-500 V

Applicable Standard: BS 5308

Construction:

Plain Annealed Copper Conductor – Class (1,2,5)

Insulation Type: P.V.C

Twisted Pair & Screen (Drain Wire + Aluminum Foil)

Screen Over Laying up Pairs: Drain Wire + Aluminum Foil

Sheath: P.V.C

- Application:

Transmission of Analog and Digital Signals in Instrumentation System, the cables are suitable to be laid indoors and outdoors, on the trays or in pipes.

No. of Cores & Cross Section (mm2) | Nominal insulation Thickness (mm) | Nominal Sheath Thickness. (mm) | Overall Dia. (Approx.)(mm) | Total Weight Approx. (kg/km) |

|---|---|---|---|---|

1×2×0.5 | 0.6 | 0.8 | 6.2 | 45 |

2×2×0.5 | 0.6 | 1.1 | 11.5 | 113 |

3×2×0.5 | 0.6 | 1.2 | 12.4 | 147 |

4×2×0.5 | 0.6 | 1.2 | 13.6 | 179 |

5×2×0.5 | 0.6 | 1.2 | 14.8 | 211 |

6×2×0.5 | 0.6 | 1.3 | 16.4 | 251 |

7×2×0.5 | 0.6 | 1.3 | 16.4 | 276 |

8×2×0.5 | 0.6 | 1.3 | 19.3 | 320 |

9×2×0.5 | 0.6 | 1.3 | 20.9 | 355 |

10×2×0.5 | 0.6 | 1.3 | 20.9 | 379 |

11×2×0.5 | 0.6 | 1.5 | 21.3 | 423 |

12×2×0.5 | 0.6 | 1.5 | 22.0 | 453 |

13×2×0.5 | 0.6 | 1.5 | 23.1 | 486 |

14×2×0.5 | 0.6 | 1.5 | 23.1 | 510 |

15×2×0.5 | 0.6 | 1.5 | 24.4 | 544 |

20×2×0.5 | 0.6 | 1.5 | 27.2 | 687 |

25×2×0.5 | 0.6 | 1.7 | 30.6 | 861 |

30×2×0.5 | 0.6 | 1.7 | 32.4 | 1000 |

35×2×0.5 | 0.6 | 2.2 | 36.1 | 1226 |

40×2×0.5 | 0.6 | 2.2 | 37.5 | 1366 |

45×2×0.5 | 0.6 | 2.2 | 40.5 | 1521 |

50×2×0.5 | 0.6 | 2.2 | 41.2 | 1652 |

No. of Cores & Cross Section (mm2) | Nominal insulation Thickness (mm) | Nominal Sheath Thickness. (mm) | Overall Dia. (Approx.)(mm) | Total Weight Approx. (kg/km) |

|---|---|---|---|---|

1×2×0.75 | 0.6 | 0.8 | 6.5 | 52 |

2×2×0.75 | 0.6 | 1.1 | 12.4 | 129 |

3×2×0.75 | 0.6 | 1.2 | 13.3 | 170 |

4×2×0.75 | 0.6 | 1.2 | 14.6 | 209 |

5×2×0.75 | 0.6 | 1.2 | 16.0 | 248 |

6×2×0.75 | 0.6 | 1.3 | 17.6 | 295 |

7×2×0.75 | 0.6 | 1.3 | 17.6 | 326 |

8×2×0.75 | 0.6 | 1.3 | 20.9 | 378 |

9×2×0.75 | 0.6 | 1.3 | 22.5 | 419 |

10×2×0.75 | 0.6 | 1.3 | 22.5 | 450 |

11×2×0.75 | 0.6 | 1.5 | 22.9 | 501 |

12×2×0.75 | 0.6 | 1.5 | 23.7 | 537 |

13×2×0.75 | 0.6 | 1.5 | 24.9 | 577 |

14×2×0.75 | 0.6 | 1.5 | 24.9 | 607 |

15×2×0.75 | 0.6 | 1.5 | 26.4 | 648 |

20×2×0.75 | 0.6 | 1.7 | 29.8 | 850 |

25×2×0.75 | 0.6 | 2.0 | 33.7 | 1076 |

30×2×0.75 | 0.6 | 2.0 | 35.7 | 1249 |

35×2×0.75 | 0.6 | 2.2 | 39.0 | 1466 |

40×2×0.75 | 0.6 | 2.2 | 40.6 | 1637 |

45×2×0.75 | 0.6 | 2.2 | 43.9 | 1825 |

50×2×0.75 | 0.6 | 2.2 | 44.6 | 1987 |

No. of Cores & Cross Section (mm2) | Nominal insulation Thickness (mm) | Nominal Sheath Thickness. (mm) | Overall Dia. (Approx.)(mm) | Total Weight Approx. (kg/km) |

|---|---|---|---|---|

1×2×1 | 0.6 | 0.8 | 6.9 | 59 |

2×2×1 | 0.6 | 1.2 | 13.3 | 151 |

3×2×1 | 0.6 | 1.3 | 14.3 | 199 |

4×2×1 | 0.6 | 1.3 | 15.7 | 244 |

5×2×1 | 0.6 | 1.3 | 17.1 | 290 |

6×2×1 | 0.6 | 1.5 | 19.1 | 355 |

7×2×1 | 0.6 | 1.5 | 19.1 | 391 |

8×2×1 | 0.6 | 1.5 | 22.6 | 453 |

9×2×1 | 0.6 | 1.5 | 24.4 | 503 |

10×2×1 | 0.6 | 1.5 | 24.4 | 539 |

11×2×1 | 0.6 | 1.7 | 24.8 | 598 |

12×2×1 | 0.6 | 1.7 | 25.6 | 641 |

13×2×1 | 0.6 | 1.7 | 26.9 | 688 |

14×2×1 | 0.6 | 1.7 | 26.9 | 725 |

15×2×1 | 0.6 | 1.7 | 28.4 | 774 |

20×2×1 | 0.6 | 1.7 | 31.8 | 981 |

25×2×1 | 0.6 | 2.0 | 35.9 | 1241 |

30×2×1 | 0.6 | 2.0 | 38.0 | 1445 |

35×2×1 | 0.6 | 2.2 | 41.5 | 1695 |

40×2×1 | 0.6 | 2.2 | 43.3 | 1896 |

45×2×1 | 0.6 | 2.2 | 46.8 | 2115 |

50×2×1 | 0.6 | 2.2 | 47.6 | 2306 |

No. of Cores & Cross Section (mm2) | Nominal insulation Thickness (mm) | Nominal Sheath Thickness. (mm) | Overall Dia. (Approx.)(mm) | Total Weight Approx. (kg/km) |

|---|---|---|---|---|

1×2×1.5 | 0.6 | 0.8 | 7.5 | 72 |

2×2×1.5 | 0.6 | 1.2 | 14.5 | 181 |

3×2×1.5 | 0.6 | 1.3 | 15.6 | 241 |

4×2×1.5 | 0.6 | 1.3 | 17.1 | 299 |

5×2×1.5 | 0.6 | 1.3 | 18.8 | 357 |

6×2×1.5 | 0.6 | 1.5 | 20.9 | 435 |

7×2×1.5 | 0.6 | 1.5 | 20.9 | 482 |

8×2×1.5 | 0.6 | 1.5 | 24.8 | 559 |

9×2×1.5 | 0.6 | 1.5 | 26.8 | 621 |

10×2×1.5 | 0.6 | 1.5 | 26.8 | 668 |

11×2×1.5 | 0.6 | 1.7 | 27.2 | 740 |

12×2×1.5 | 0.6 | 1.7 | 28.1 | 795 |

13×2×1.5 | 0.6 | 1.7 | 29.6 | 855 |

14×2×1.5 | 0.6 | 1.7 | 29.6 | 902 |

15×2×1.5 | 0.6 | 1.7 | 31.3 | 964 |

20×2×1.5 | 0.6 | 1.7 | 35.0 | 1230 |

25×2×1.5 | 0.6 | 2.0 | 39.5 | 1554 |

30×2×1.5 | 0.6 | 2.0 | 41.9 | 1815 |

35×2×1.5 | 0.6 | 2.2 | 45.7 | 2128 |

40×2×1.5 | 0.6 | 2.2 | 47.6 | 2387 |

45×2×1.5 | 0.6 | 2.2 | 51.6 | 2666 |

50×2×1.5 | 0.6 | 2.2 | 52.4 | 2914 |

Armored Multi-Pair/ Triple Screened Instrument Cables MSR-Y (ST) YRY

- Voltage Rate: 300-500 V

Applicable Standard: BS 5308

Construction:

Plain Annealed Copper Conductor – Class (1,2,5)

Insulation Type: P.V.C

Twisted Pair

Screen Over Laying up Pairs: Drain Wire + Aluminum Foil

Inner Sheath: P.V.C

Armor: Galvanized Steel Wire

Sheath: P.V.C

- Application:

Transmission of Analog and Digital Signals in Instrumentation System, the cables are suitable to be laid indoors and outdoors, on cable trays or in pipes or in earth.

No. of Cores & Cross Section (mm2) | Nominal insulation Thickness (mm) | Nominal Inner Layer Thickness (mm) | Armour Wire Dia. (mm) | Nominal Sheath Thickness. (mm) | Overall Dia. (Approx.)(mm) | Total Weight Approx. (kg/km) |

|---|---|---|---|---|---|---|

1×2×0.5 | 0.6 | 0.8 | 0.9 | 1.3 | 10.6 | 221 |

2×2×0.5 | 0.6 | 0.8 | 0.9 | 1.3 | 12.9 | 306 |

3×2×0.5 | 0.6 | 1.2 | 0.9 | 1.5 | 14.7 | 382 |

4×2×0.5 | 0.6 | 1.2 | 1.25 | 1.5 | 16.5 | 518 |

5×2×0.5 | 0.6 | 1.2 | 1.25 | 1.5 | 17.5 | 578 |

6×2×0.5 | 0.6 | 1.3 | 1.25 | 1.6 | 18.8 | 642 |

7×2×0.5 | 0.6 | 1.3 | 1.25 | 1.6 | 19.6 | 690 |

8×2×0.5 | 0.6 | 1.3 | 1.25 | 1.6 | 20.2 | 736 |

9×2×0.5 | 0.6 | 1.3 | 1.6 | 1.6 | 21.8 | 911 |

10×2×0.5 | 0.6 | 1.3 | 1.6 | 1.6 | 22.4 | 953 |

11×2×0.5 | 0.6 | 1.5 | 1.6 | 1.7 | 23.6 | 1039 |

12×2×0.5 | 0.6 | 1.5 | 1.6 | 1.7 | 24.3 | 1082 |

13×2×0.5 | 0.6 | 1.5 | 1.6 | 1.7 | 24.7 | 1122 |

14×2×0.5 | 0.6 | 1.5 | 1.6 | 1.7 | 25.3 | 1165 |

15×2×0.5 | 0.6 | 1.5 | 1.6 | 1.7 | 25.9 | 1207 |

20×2×0.5 | 0.6 | 1.5 | 1.6 | 1.8 | 28.4 | 1408 |

25×2×0.5 | 0.6 | 1.7 | 1.6 | 1.9 | 31.4 | 1650 |

30×2×0.5 | 0.6 | 1.7 | 2.0 | 1.9 | 34.0 | 2058 |

35×2×0.5 | 0.6 | 2.2 | 2.0 | 2.1 | 37.1 | 2379 |

40×2×0.5 | 0.6 | 2.2 | 2.0 | 2.1 | 38.8 | 2574 |

45×2×0.5 | 0.6 | 2.2 | 2.0 | 2.1 | 40.5 | 2745 |

50×2×0.5 | 0.6 | 2.2 | 2.0 | 2.1 | 42.0 | 2910 |

No. of Cores & Cross Section (mm2) | Nominal insulation Thickness (mm) | Nominal Inner Layer Thickness (mm) | Armour Wire Dia. (mm) | Nominal Sheath Thickness. (mm) | Overall Dia. (Approx.)(mm) | Total Weight Approx. (kg/km) |

|---|---|---|---|---|---|---|

1×2×0.75 | 0.6 | 0.8 | 0.9 | 1.3 | 11.0 | 236 |

2×2×0.75 | 0.6 | 1.1 | 0.9 | 1.4 | 13.6 | 340 |

3×2×0.75 | 0.6 | 1.2 | 1.25 | 1.5 | 16.1 | 514 |

4×2×0.75 | 0.6 | 1.2 | 1.25 | 1.5 | 17.3 | 571 |

5×2×0.75 | 0.6 | 1.2 | 1.25 | 1.5 | 18.4 | 638 |

6×2×0.75 | 0.6 | 1.3 | 1.25 | 1.7 | 20.0 | 728 |

7×2×0.75 | 0.6 | 1.3 | 1.25 | 1.7 | 20.9 | 784 |

8×2×0.75 | 0.6 | 1.3 | 1.6 | 1.7 | 22.3 | 953 |

9×2×0.75 | 0.6 | 1.3 | 1.6 | 1.7 | 23.2 | 1021 |

10×2×0.75 | 0.6 | 1.3 | 1.6 | 1.7 | 23.9 | 1070 |

11×2×0.75 | 0.6 | 1.5 | 1.6 | 1.8 | 25.2 | 1166 |

12×2×0.75 | 0.6 | 1.5 | 1.6 | 1.8 | 25.9 | 1232 |

13×2×0.75 | 0.6 | 1.5 | 1.6 | 1.8 | 26.3 | 1278 |

14×2×0.75 | 0.6 | 1.5 | 1.6 | 1.8 | 27.0 | 1328 |

15×2×0.75 | 0.6 | 1.5 | 1.6 | 1.8 | 27.7 | 1377 |

20×2×0.75 | 0.6 | 1.7 | 1.6 | 2.0 | 31.1 | 1668 |

25×2×0.75 | 0.6 | 2.0 | 2.0 | 2.0 | 35.0 | 2199 |

30×2×0.75 | 0.6 | 2.0 | 2.0 | 2.0 | 37.1 | 2428 |

35×2×0.75 | 0.6 | 2.2 | 2.0 | 2.2 | 39.7 | 2745 |

40×2×0.75 | 0.6 | 2.2 | 2.0 | 2.2 | 41.6 | 2948 |

45×2×0.75 | 0.6 | 2.2 | 2.0 | 2.2 | 43.4 | 3176 |

50×2×0.75 | 0.6 | 2.2 | 2.5 | 2.2 | 46.1 | 3794 |

No. of Cores & Cross Section (mm2) | Nominal insulation Thickness (mm) | Nominal Inner Layer Thickness (mm) | Armour Wire Dia. (mm) | Nominal Sheath Thickness. (mm) | Overall Dia. (Approx.)(mm) | Total Weight Approx. (kg/km) |

|---|---|---|---|---|---|---|

1×2×1 | 0.6 | 0.8 | 0.9 | 1.4 | 11.6 | 256 |

2×2×1 | 0.6 | 1.2 | 0.9 | 1.4 | 14.3 | 373 |

3×2×1 | 0.6 | 1.3 | 1.25 | 1.6 | 17.1 | 562 |

4×2×1 | 0.6 | 1.3 | 1.25 | 1.6 | 18.4 | 637 |

5×2×1 | 0.6 | 1.3 | 1.25 | 1.6 | 19.6 | 712 |

6×2×1 | 0.6 | 1.5 | 1.6 | 1.8 | 22.1 | 957 |

7×2×1 | 0.6 | 1.5 | 1.6 | 1.8 | 23.1 | 1033 |

8×2×1 | 0.6 | 1.5 | 1.6 | 1.8 | 23.9 | 1089 |

9×2×1 | 0.6 | 1.5 | 1.6 | 1.8 | 24.9 | 1165 |

10×2×1 | 0.6 | 1.3 | 1.6 | 1.7 | 23.9 | 1070 |

11×2×1 | 0.6 | 1.7 | 1.6 | 1.9 | 27.0 | 1327 |

12×2×1 | 0.6 | 1.7 | 1.6 | 1.9 | 27.7 | 1400 |

13×2×1 | 0.6 | 1.7 | 1.6 | 1.9 | 28.2 | 1453 |

14×2×1 | 0.6 | 1.7 | 1.6 | 1.9 | 28.9 | 1510 |

15×2×1 | 0.6 | 1.7 | 1.6 | 1.9 | 29.7 | 1567 |

20×2×1 | 0.6 | 1.7 | 2.0 | 2.0 | 33.4 | 2086 |

25×2×1 | 0.6 | 2.0 | 2.0 | 2.1 | 37.0 | 2462 |

30×2×1 | 0.6 | 2.0 | 2.0 | 2.1 | 39.2 | 2722 |

35×2×1 | 0.6 | 2.2 | 2.0 | 2.4 | 42.2 | 3094 |

40×2×1 | 0.6 | 2.2 | 2.5 | 2.4 | 45.2 | 3723 |

45×2×1 | 0.6 | 2.2 | 2.5 | 2.4 | 47.2 | 4025 |

50×2×1 | 0.6 | 2.2 | 2.5 | 2.4 | 48.9 | 4283 |

No. of Cores & Cross Section (mm2) | Nominal insulation Thickness (mm) | Nominal Inner Layer Thickness (mm) | Armour Wire Dia. (mm) | Nominal Sheath Thickness. (mm) | Overall Dia. (Approx.)(mm) | Total Weight Approx. (kg/km) |

|---|---|---|---|---|---|---|

1×2×1.5 | 0.6 | 0.8 | 0.9 | 1.4 | 12.2 | 283 |

2×2×1.5 | 0.6 | 1.2 | 1.25 | 1.4 | 15.9 | 506 |

3×2×1.5 | 0.6 | 1.3 | 1.25 | 1.6 | 18.2 | 638 |

4×2×1.5 | 0.6 | 1.3 | 1.25 | 1.6 | 19.6 | 726 |

5×2×1.5 | 0.6 | 1.3 | 1.6 | 1.6 | 21.6 | 950 |

6×2×1.5 | 0.6 | 1.5 | 1.6 | 1.8 | 23.6 | 1076 |

7×2×1.5 | 0.6 | 1.5 | 1.6 | 1.8 | 24.7 | 1164 |

8×2×1.5 | 0.6 | 1.5 | 1.6 | 1.8 | 25.5 | 1248 |

9×2×1.5 | 0.6 | 1.5 | 1.6 | 1.8 | 26.6 | 1337 |

10×2×1.5 | 0.6 | 1.5 | 1.6 | 1.8 | 27.5 | 1421 |

11×2×1.5 | 0.6 | 1.7 | 1.6 | 1.9 | 28.9 | 1541 |

12×2×1.5 | 0.6 | 1.7 | 1.6 | 1.9 | 29.7 | 1611 |

13×2×1.5 | 0.6 | 1.7 | 1.6 | 1.9 | 30.3 | 1675 |

14×2×1.5 | 0.6 | 1.7 | 1.6 | 1.9 | 31.1 | 1761 |

15×2×1.5 | 0.6 | 1.7 | 1.6 | 1.9 | 32.0 | 1846 |

20×2×1.5 | 0.6 | 1.7 | 2.0 | 2.0 | 36.0 | 2446 |

25×2×1.5 | 0.6 | 2.0 | 2.0 | 2.1 | 39.9 | 2887 |

30×2×1.5 | 0.6 | 2.0 | 2.0 | 2.1 | 42.4 | 3231 |

35×2×1.5 | 0.6 | 2.2 | 2.5 | 2.4 | 46.7 | 4065 |

40×2×1.5 | 0.6 | 2.2 | 2.5 | 2.4 | 48.9 | 4426 |

45×2×1.5 | 0.6 | 2.2 | 2.5 | 2.4 | 51.1 | 4748 |

50×2×1.5 | 0.6 | 2.2 | 2.5 | 2.4 | 53.1 | 5103 |

No. of Cores & Cross Section (mm2) | Nominal insulation Thickness (mm) | Nominal Inner Layer Thickness (mm) | Armour Wire Dia. (mm) | Nominal Sheath Thickness. (mm) | Overall Dia. (Approx.)(mm) | Total Weight Approx. (kg/km) |

|---|---|---|---|---|---|---|

1×3×0.5 | 0.6 | 1.2 | 0.9 | 1.3 | 11.7 | 266 |

2×3×0.5 | 0.6 | 1.3 | 1.25 | 1.5 | 17.5 | 549 |

3×3×0.5 | 0.6 | 1.4 | 1.25 | 1.5 | 18.5 | 611 |

4×3×0.5 | 0.6 | 1.4 | 1.25 | 1.6 | 19.9 | 692 |

5×3×0.5 | 0.6 | 1.4 | 1.6 | 1.7 | 22.0 | 901 |

6×3×0.5 | 0.6 | 1.5 | 1.6 | 1.7 | 23.6 | 1004 |

7×3×0.5 | 0.6 | 1.5 | 1.6 | 1.7 | 23.6 | 1030 |

8×3×0.5 | 0.6 | 1.6 | 1.6 | 1.8 | 27.0 | 1221 |

9×3×0.5 | 0.6 | 1.6 | 1.6 | 1.9 | 28.7 | 1332 |

10×3×0.5 | 0.6 | 1.6 | 1.6 | 1.9 | 28.7 | 1358 |

11×3×0.5 | 0.6 | 1.6 | 1.6 | 1.9 | 28.7 | 1384 |

12×3×0.5 | 0.6 | 1.7 | 1.6 | 1.9 | 29.6 | 1450 |

13×3×0.5 | 0.6 | 1.7 | 1.6 | 1.9 | 30.8 | 1527 |

14×3×0.5 | 0.6 | 1.7 | 1.6 | 1.9 | 30.8 | 1553 |

15×3×0.5 | 0.6 | 1.8 | 2.0 | 2.0 | 33.3 | 1909 |

20×3×0.5 | 0.6 | 1.9 | 2.0 | 2.1 | 36.6 | 2224 |

25×3×0.5 | 0.6 | 2.0 | 2.0 | 2.2 | 40.0 | 2570 |

30×3×0.5 | 0.6 | 2.0 | 2.0 | 2.3 | 42.1 | 2830 |

35×3×0.5 | 0.6 | 2.1 | 2.5 | 2.4 | 46.1 | 3535 |

40×3×0.5 | 0.6 | 2.2 | 2.5 | 2.5 | 48.0 | 3815 |

45×3×0.5 | 0.6 | 2.3 | 2.5 | 2.6 | 51.5 | 4212 |

50×3×0.5 | 0.6 | 2.3 | 2.5 | 2.6 | 52.1 | 4396 |

No. of Cores & Cross Section (mm2) | Nominal insulation Thickness (mm) | Nominal Inner Layer Thickness (mm) | Armour Wire Dia. (mm) | Nominal Sheath Thickness. (mm) | Overall Dia. (Approx.)(mm) | Total Weight Approx. (kg/km) |

|---|---|---|---|---|---|---|

1×3×0.75 | 0.6 | 1.2 | 0.9 | 1.3 | 12.2 | 290 |

2×3×0.75 | 0.6 | 1.4 | 1.25 | 1.5 | 18.7 | 615 |

3×3×0.75 | 0.6 | 1.4 | 1.25 | 1.6 | 19.7 | 679 |

4×3×0.75 | 0.6 | 1.4 | 1.6 | 1.6 | 21.6 | 897 |

5×3×0.75 | 0.6 | 1.5 | 1.6 | 1.7 | 23.4 | 1019 |

6×3×0.75 | 0.6 | 1.5 | 1.6 | 1.8 | 25.1 | 1120 |

7×3×0.75 | 0.6 | 1.5 | 1.6 | 1.8 | 25.1 | 1154 |

8×3×0.75 | 0.6 | 1.7 | 1.6 | 1.9 | 29.0 | 1388 |

9×3×0.75 | 0.6 | 1.7 | 1.6 | 1.9 | 30.7 | 1500 |

10×3×0.75 | 0.6 | 1.7 | 1.6 | 1.9 | 30.7 | 1534 |

11×3×0.75 | 0.6 | 1.7 | 1.6 | 1.9 | 30.7 | 1568 |

12×3×0.75 | 0.6 | 1.7 | 1.6 | 2.0 | 31.7 | 1663 |

13×3×0.75 | 0.6 | 1.8 | 2.0 | 2.0 | 34.0 | 2005 |

14×3×0.75 | 0.6 | 1.8 | 2.0 | 2.0 | 34.0 | 2040 |

15×3×0.75 | 0.6 | 1.8 | 2.0 | 2.1 | 35.6 | 2166 |

20×3×0.75 | 0.6 | 1.9 | 2.0 | 2.2 | 39.2 | 2558 |

25×3×0.75 | 0.6 | 2.1 | 2.0 | 2.3 | 43.1 | 2975 |

30×3×0.75 | 0.6 | 2.1 | 2.5 | 2.5 | 46.6 | 3727 |

35×3×0.75 | 0.6 | 2.2 | 2.5 | 2.6 | 49.9 | 4122 |

40×3×0.75 | 0.6 | 2.3 | 2.5 | 2.6 | 51.7 | 4430 |

45×3×0.75 | 0.6 | 2.4 | 2.5 | 2.8 | 55.7 | 4948 |

50×3×0.75 | 0.6 | 2.4 | 2.5 | 2.8 | 56.4 | 5176 |

No. of Cores & Cross Section (mm2) | Nominal insulation Thickness (mm) | Nominal Inner Layer Thickness (mm) | Armour Wire Dia. (mm) | Nominal Sheath Thickness. (mm) | Overall Dia. (Approx.)(mm) | Total Weight Approx. (kg/km) |

|---|---|---|---|---|---|---|

1×3×1 | 0.6 | 1.2 | 0.9 | 1.3 | 12.6 | 308 |

2×3×1 | 0.6 | 1.4 | 1.25 | 1.6 | 19.6 | 661 |

3×3×1 | 0.6 | 1.4 | 1.25 | 1.6 | 20.5 | 735 |

4×3×1 | 0.6 | 1.5 | 1.6 | 1.7 | 23.0 | 995 |

5×3×1 | 0.6 | 1.5 | 1.6 | 1.7 | 24.5 | 1093 |

6×3×1 | 0.6 | 1.6 | 1.6 | 1.8 | 26.5 | 1289 |

7×3×1 | 0.6 | 1.6 | 1.6 | 1.8 | 26.5 | 1289 |

8×3×1 | 0.6 | 1.7 | 1.6 | 1.9 | 30.5 | 1527 |

9×3×1 | 0.6 | 1.8 | 2.0 | 2.0 | 33.5 | 1909 |

10×3×1 | 0.6 | 1.8 | 2.0 | 2.0 | 33.5 | 1951 |

11×3×1 | 0.6 | 1.8 | 2.0 | 2.0 | 33.5 | 1994 |

12×3×1 | 0.6 | 1.8 | 2.0 | 2.1 | 34.5 | 2093 |

13×3×1 | 0.6 | 1.8 | 2.0 | 2.1 | 35.9 | 2210 |

14×3×1 | 0.6 | 1.8 | 2.0 | 2.1 | 35.9 | 2253 |

15×3×1 | 0.6 | 1.9 | 2.0 | 2.2 | 37.9 | 2431 |

20×3×1 | 0.6 | 2.0 | 2.0 | 2.3 | 41.6 | 2875 |

25×3×1 | 0.6 | 2.1 | 2.5 | 2.5 | 46.8 | 3768 |

30×3×1 | 0.6 | 2.2 | 2.5 | 2.5 | 49.3 | 4166 |

35×3×1 | 0.6 | 2.3 | 2.5 | 2.7 | 53.0 | 4675 |

40×3×1 | 0.6 | 2.4 | 2.5 | 2.7 | 55.0 | 5030 |

45×3×1 | 0.6 | 2.5 | 2.5 | 2.9 | 59.2 | 5603 |

50×3×1 | 0.6 | 2.5 | 2.5 | 2.9 | 60.0 | 5875 |

No. of Cores & Cross Section (mm2) | Nominal insulation Thickness (mm) | Nominal Inner Layer Thickness (mm) | Armour Wire Dia. (mm) | Nominal Sheath Thickness. (mm) | Overall Dia. (Approx.)(mm) | Total Weight Approx. (kg/km) |

|---|---|---|---|---|---|---|

1×3×1.5 | 0.6 | 1.2 | 0.9 | 1.4 | 13.4 | 348 |

2×3×1.5 | 0.6 | 1.4 | 1.6 | 1.6 | 21.6 | 877 |

3×3×1.5 | 0.6 | 1.5 | 1.6 | 1.7 | 23.0 | 1001 |

4×3×1.5 | 0.6 | 1.5 | 1.6 | 1.7 | 24.6 | 1131 |

5×3×1.5 | 0.6 | 1.6 | 1.6 | 1.8 | 26.6 | 1286 |

6×3×1.5 | 0.6 | 1.6 | 1.6 | 1.9 | 28.7 | 1435 |

7×3×1.5 | 0.6 | 1.6 | 1.6 | 1.9 | 28.7 | 1494 |

8×3×1.5 | 0.6 | 1.8 | 2.0 | 2.1 | 34.2 | 2045 |

9×3×1.5 | 0.6 | 1.9 | 2.0 | 2.1 | 36.5 | 2231 |

10×3×1.5 | 0.6 | 1.9 | 2.0 | 2.1 | 36.5 | 2290 |

11×3×1.5 | 0.6 | 1.9 | 2.0 | 2.1 | 36.5 | 2348 |

12×3×1.5 | 0.6 | 1.9 | 2.0 | 2.2 | 37.6 | 2492 |

13×3×1.5 | 0.6 | 1.9 | 2.0 | 2.2 | 39.2 | 2630 |

14×3×1.5 | 0.6 | 1.9 | 2.0 | 2.2 | 39.2 | 2688 |

15×3×1.5 | 0.6 | 2.0 | 2.0 | 2.3 | 41.3 | 2891 |

20×3×1.5 | 0.6 | 2.1 | 2.5 | 2.5 | 46.7 | 3873 |

25×3×1.5 | 0.6 | 2.3 | 2.5 | 2.6 | 51.3 | 4515 |

30×3×1.5 | 0.6 | 2.4 | 2.5 | 2.7 | 54.2 | 5028 |

35×3×1.5 | 0.6 | 2.5 | 2.5 | 2.8 | 58.2 | 5652 |

40×3×1.5 | 0.6 | 2.6 | 2.5 | 2.9 | 60.5 | 6125 |

45×3×1.5 | 0.6 | 2.7 | 2.5 | 3.1 | 65.2 | 6804 |

50×3×1.5 | 0.6 | 2.7 | 2.5 | 3.1 | 66.1 | 7161 |

Armored Multi-Pair/ Individual Screened Instrument Cables MSR-Y (ST) YRY-PIMF

- Voltage Rate: 300-500 V

Applicable Standard: BS 5308

Construction:

Plain Annealed Copper Conductor – Class (1,2,5)

Insulation Type: P.V.C

Twisted Pair & Screen (Drain Wire + Aluminum Foil)

Screen Over Laying up Pairs: Drain Wire + Aluminum Foil

Inner Sheath: P.V.C

Armor: Galvanized Steel Wire

Sheath: P.V.C

- Application:

Transmission of Analog and Digital Signals in Instrumentation System, the cables are suitable to be laid indoors and outdoors, on cable trays or in pipes or in earth.

No. of Cores & Cross Section (mm2) | Nominal insulation Thickness (mm) | Nominal Inner Layer Thickness (mm) | Armour Wire Dia. (mm) | Nominal Sheath Thickness. (mm) | Overall Dia. (Approx.)(mm) | Total Weight Approx. (kg/km) |

|---|---|---|---|---|---|---|

1×2×0.5 | 0.6 | 0.8 | 0.9 | 1.3 | 10.6 | 221 |

2×2×0.5 | 0.6 | 1.1 | 1.25 | 1.5 | 17.0 | 521 |

3×2×0.5 | 0.6 | 1.2 | 1.25 | 1.6 | 18.1 | 590 |

4×2×0.5 | 0.6 | 1.2 | 1.25 | 1.6 | 19.3 | 659 |

5×2×0.5 | 0.6 | 1.2 | 1.25 | 1.6 | 20.5 | 730 |

6×2×0.5 | 0.6 | 1.3 | 1.6 | 1.8 | 23.2 | 970 |

7×2×0.5 | 0.6 | 1.3 | 1.6 | 1.8 | 23.2 | 995 |

8×2×0.5 | 0.6 | 1.3 | 1.6 | 1.8 | 26.1 | 1143 |

9×2×0.5 | 0.6 | 1.3 | 1.6 | 1.8 | 27.7 | 1238 |

10×2×0.5 | 0.6 | 1.3 | 1.6 | 1.8 | 27.7 | 1263 |

11×2×0.5 | 0.6 | 1.5 | 1.6 | 1.8 | 28.1 | 1326 |

12×2×0.5 | 0.6 | 1.5 | 1.6 | 1.8 | 28.8 | 1377 |

13×2×0.5 | 0.6 | 1.5 | 1.6 | 1.8 | 29.9 | 1451 |

14×2×0.5 | 0.6 | 1.5 | 1.6 | 1.8 | 29.9 | 1476 |

15×2×0.5 | 0.6 | 1.5 | 1.6 | 1.8 | 31.2 | 1553 |

20×2×0.5 | 0.6 | 1.5 | 1.6 | 1.8 | 28.4 | 1408 |

25×2×0.5 | 0.6 | 1.7 | 2.0 | 2.1 | 38.8 | 2436 |

30×2×0.5 | 0.6 | 1.7 | 2.0 | 2.1 | 40.6 | 2642 |

35×2×0.5 | 0.6 | 2.2 | 2.5 | 2.4 | 45.9 | 3497 |

40×2×0.5 | 0.6 | 2.2 | 2.5 | 2.4 | 47.3 | 3731 |

45×2×0.5 | 0.6 | 2.2 | 2.5 | 2.4 | 50.3 | 4036 |

50×2×0.5 | 0.6 | 2.2 | 2.5 | 2.4 | 51.0 | 4213 |

No. of Cores & Cross Section (mm2) | Nominal insulation Thickness (mm) | Nominal Inner Layer Thickness (mm) | Armour Wire Dia. (mm) | Nominal Sheath Thickness. (mm) | Overall Dia. (Approx.)(mm) | Total Weight Approx. (kg/km) |

|---|---|---|---|---|---|---|

1×2×0.75 | 0.6 | 0.8 | 0.9 | 1.3 | 10.9 | 236 |

2×2×0.75 | 0.6 | 1.1 | 1.25 | 1.5 | 17.9 | 563 |

3×2×0.75 | 0.6 | 1.2 | 1.25 | 1.6 | 19.0 | 639 |

4×2×0.75 | 0.6 | 1.2 | 1.25 | 1.6 | 20.3 | 716 |

5×2×0.75 | 0.6 | 1.2 | 1.6 | 1.6 | 22.4 | 927 |

6×2×0.75 | 0.6 | 1.3 | 1.6 | 1.8 | 24.4 | 1057 |

7×2×0.75 | 0.6 | 1.3 | 1.6 | 1.8 | 14.4 | 1087 |

8×2×0.75 | 0.6 | 1.3 | 1.6 | 1.8 | 27.7 | 1261 |

9×2×0.75 | 0.6 | 1.3 | 1.6 | 1.8 | 29.3 | 1365 |

10×2×0.75 | 0.6 | 1.3 | 1.6 | 1.8 | 29.3 | 1395 |

11×2×0.75 | 0.6 | 1.5 | 1.6 | 1.9 | 29.9 | 1479 |

12×2×0.75 | 0.6 | 1.5 | 1.6 | 1.9 | 30.7 | 1538 |

13×2×0.75 | 0.6 | 1.5 | 1.6 | 1.9 | 31.9 | 1620 |

14×2×0.75 | 0.6 | 1.5 | 1.6 | 1.9 | 31.9 | 1651 |

15×2×0.75 | 0.6 | 1.5 | 2.0 | 1.9 | 34.2 | 1977 |

20×2×0.75 | 0.6 | 1.7 | 2.0 | 2.0 | 37.8 | 2351 |

25×2×0.75 | 0.6 | 2.0 | 2.0 | 2.2 | 42.1 | 2800 |

30×2×0.75 | 0.6 | 2.0 | 2.5 | 2.2 | 45.1 | 3475 |

35×2×0.75 | 0.6 | 2.2 | 2.5 | 2.5 | 49.0 | 3908 |

40×2×0.75 | 0.6 | 2.2 | 2.5 | 2.5 | 50.6 | 4176 |

45×2×0.75 | 0.6 | 2.2 | 2.5 | 2.5 | 53.9 | 4557 |

50×2×0.75 | 0.6 | 2.2 | 2.5 | 2.5 | 54.6 | 4766 |

No. of Cores & Cross Section (mm2) | Nominal insulation Thickness (mm) | Nominal Inner Layer Thickness (mm) | Armour Wire Dia. (mm) | Nominal Sheath Thickness. (mm) | Overall Dia. (Approx.)(mm) | Total Weight Approx. (kg/km) |

|---|---|---|---|---|---|---|

1×2×1 | 0.6 | 0.8 | 0.9 | 1.4 | 11.5 | 255 |

2×2×1 | 0.6 | 1.2 | 1.25 | 1.6 | 19.0 | 619 |

3×2×1 | 0.6 | 1.3 | 1.25 | 1.7 | 20.2 | 704 |

4×2×1 | 0.6 | 1.3 | 1.6 | 1.7 | 22.3 | 915 |

5×2×1 | 0.6 | 1.3 | 1.6 | 1.7 | 23.7 | 1021 |

6×2×1 | 0.6 | 1.5 | 1.6 | 1.9 | 26.1 | 1188 |

7×2×1 | 0.6 | 1.5 | 1.6 | 1.9 | 26.1 | 1224 |

8×2×1 | 0.6 | 1.5 | 1.6 | 1.9 | 29.6 | 1412 |

9×2×1 | 0.6 | 1.5 | 1.6 | 1.9 | 31.4 | 1525 |

10×2×1 | 0.6 | 1.5 | 1.6 | 1.9 | 31.4 | 1562 |

11×2×1 | 0.6 | 1.7 | 1.6 | 2.0 | 32.0 | 1654 |

12×2×1 | 0.6 | 1.7 | 2.0 | 2.0 | 33.6 | 1953 |

13×2×1 | 0.6 | 1.7 | 2.0 | 2.0 | 34.9 | 2063 |

14×2×1 | 0.6 | 1.7 | 2.0 | 2.0 | 34.9 | 2099 |

15×2×1 | 0.6 | 1.7 | 2.0 | 2.0 | 36.4 | 2212 |

20×2×1 | 0.6 | 1.7 | 2.0 | 2.1 | 40.0 | 2592 |

25×2×1 | 0.6 | 2.0 | 2.5 | 2.4 | 45.7 | 3510 |

30×2×1 | 0.6 | 2.0 | 2.5 | 2.4 | 47.8 | 3815 |

35×2×1 | 0.6 | 2.2 | 2.5 | 2.7 | 51.9 | 4330 |

40×2×1 | 0.6 | 2.2 | 2.5 | 2.7 | 53.7 | 4669 |

45×2×1 | 0.6 | 2.2 | 2.5 | 2.7 | 57.2 | 5088 |

50×2×1 | 0.6 | 2.2 | 2.5 | 2.7 | 58.0 | 5328 |

No. of Cores & Cross Section (mm2) | Nominal insulation Thickness (mm) | Nominal Inner Layer Thickness (mm) | Armour Wire Dia. (mm) | Nominal Sheath Thickness. (mm) | Overall Dia. (Approx.)(mm) | Total Weight Approx. (kg/km) |

|---|---|---|---|---|---|---|

1×2×1.5 | 0.6 | 0.8 | 0.9 | 1.4 | 12.1 | 282 |

2×2×1.5 | 0.6 | 1.2 | 1.25 | 1.6 | 20.2 | 687 |

3×2×1.5 | 0.6 | 1.3 | 1.6 | 1.7 | 22.2 | 912 |

4×2×1.5 | 0.6 | 1.3 | 1.6 | 1.7 | 23.7 | 1029 |

5×2×1.5 | 0.6 | 1.3 | 1.6 | 1.7 | 25.4 | 1148 |

6×2×1.5 | 0.6 | 1.5 | 1.6 | 1.9 | 27.9 | 1332 |

7×2×1.5 | 0.6 | 1.5 | 1.6 | 1.9 | 27.9 | 1379 |

8×2×1.5 | 0.6 | 1.5 | 1.6 | 1.9 | 31.8 | 1601 |

9×2×1.5 | 0.6 | 1.5 | 2.0 | 1.9 | 34.6 | 1978 |

10×2×1.5 | 0.6 | 1.5 | 2.0 | 1.9 | 34.6 | 2025 |

11×2×1.5 | 0.6 | 1.7 | 2.0 | 2.0 | 35.2 | 2142 |

12×2×1.5 | 0.6 | 1.7 | 2.0 | 2.0 | 36.1 | 2230 |

13×2×1.5 | 0.6 | 1.7 | 2.0 | 2.0 | 37.6 | 2353 |

14×2×1.5 | 0.6 | 1.7 | 2.0 | 2.0 | 37.6 | 2400 |

15×2×1.5 | 0.6 | 1.7 | 2.0 | 2.0 | 39.3 | 2553 |

20×2×1.5 | 0.6 | 1.7 | 2.0 | 2.1 | 43.2 | 2996 |

25×2×1.5 | 0.6 | 2.0 | 2.5 | 2.4 | 49.3 | 4018 |

30×2×1.5 | 0.6 | 2.0 | 2.5 | 2.4 | 51.7 | 4422 |

35×2×1.5 | 0.6 | 2.2 | 2.5 | 2.7 | 56.1 | 5010 |

40×2×1.5 | 0.6 | 2.2 | 2.5 | 2.7 | 58.0 | 5409 |

45×2×1.5 | 0.6 | 2.2 | 2.5 | 2.7 | 62.0 | 5893 |

50×2×1.5 | 0.6 | 2.2 | 2.5 | 2.7 | 62.8 | 6191 |

No. of Cores & Cross Section (mm2) | Nominal insulation Thickness (mm) | Nominal Inner Layer Thickness (mm) | Armour Wire Dia. (mm) | Nominal Sheath Thickness. (mm) | Overall Dia. (Approx.)(mm) | Total Weight Approx. (kg/km) |

|---|---|---|---|---|---|---|

1×3×0.5 | 0.6 | 1.2 | 0.9 | 1.3 | 11.7 | 265 |

2×3×0.5 | 0.6 | 1.3 | 1.25 | 1.5 | 18.0 | 580 |

3×3×0.5 | 0.6 | 1.4 | 1.25 | 1.6 | 19.2 | 659 |

4×3×0.5 | 0.6 | 1.4 | 1.25 | 1.6 | 20.4 | 740 |

5×3×0.5 | 0.6 | 1.5 | 1.6 | 1.7 | 22.9 | 973 |

6×3×0.5 | 0.6 | 1.5 | 1.6 | 1.7 | 24.3 | 1076 |

7×3×0.5 | 0.6 | 1.5 | 1.6 | 1.7 | 24.3 | 1110 |

8×3×0.5 | 0.6 | 1.6 | 1.6 | 1.8 | 27.8 | 1311 |

9×3×0.5 | 0.6 | 1.7 | 1.6 | 1.9 | 29.9 | 1460 |

10×3×0.5 | 0.6 | 1.7 | 1.6 | 1.9 | 29.9 | 1493 |

11×3×0.5 | 0.6 | 1.7 | 1.6 | 1.9 | 29.9 | 1526 |

12×3×0.5 | 0.6 | 1.7 | 1.6 | 1.9 | 30.6 | 1589 |

13×3×0.5 | 0.6 | 1.7 | 1.6 | 2.0 | 32.0 | 1689 |

14×3×0.5 | 0.6 | 1.7 | 1.6 | 2.0 | 32.0 | 1722 |

15×3×0.5 | 0.6 | 1.8 | 2.0 | 2.1 | 34.6 | 2082 |

20×3×0.5 | 0.6 | 1.9 | 2.0 | 2.2 | 38.0 | 2461 |

25×3×0.5 | 0.6 | 2.0 | 2.0 | 2.3 | 41.6 | 2850 |

30×3×0.5 | 0.6 | 2.1 | 2.5 | 2.4 | 44.9 | 3564 |

35×3×0.5 | 0.6 | 2.2 | 2.5 | 2.5 | 48.2 | 3950 |

40×3×0.5 | 0.6 | 2.2 | 2.5 | 2.6 | 49.9 | 4253 |

45×3×0.5 | 0.6 | 2.3 | 2.5 | 2.7 | 53.5 | 4694 |

50×3×0.5 | 0.6 | 2.4 | 2.5 | 2.7 | 54.4 | 4941 |

No. of Cores & Cross Section (mm2) | Nominal insulation Thickness (mm) | Nominal Inner Layer Thickness (mm) | Armour Wire Dia. (mm) | Nominal Sheath Thickness. (mm) | Overall Dia. (Approx.)(mm) | Total Weight Approx. (kg/km) |

|---|---|---|---|---|---|---|

1×3×0.75 | 0.6 | 1.2 | 0.9 | 1.3 | 12.1 | 289 |

2×3×0.75 | 0.6 | 1.4 | 1.25 | 1.6 | 19.4 | 657 |

3×3×0.75 | 0.6 | 1.4 | 1.25 | 1.6 | 20.3 | 731 |

4×3×0.75 | 0.6 | 1.5 | 1.6 | 1.7 | 22.7 | 973 |

5×3×0.75 | 0.6 | 1.5 | 1.6 | 1.7 | 24.2 | 1086 |

6×3×0.75 | 0.6 | 1.6 | 1.6 | 1.8 | 26.2 | 1223 |

7×3×0.75 | 0.6 | 1.6 | 1.6 | 1.8 | 26.2 | 1265 |

8×3×0.75 | 0.6 | 1.7 | 1.6 | 1.9 | 30.1 | 1501 |

9×3×0.75 | 0.6 | 1.8 | 1.6 | 2.0 | 32.3 | 1666 |

10×3×0.75 | 0.6 | 1.8 | 1.6 | 2.0 | 32.3 | 1708 |

11×3×0.75 | 0.6 | 1.8 | 1.6 | 2.0 | 32.3 | 1750 |

12×3×0.75 | 0.6 | 1.8 | 2.0 | 2.0 | 33.9 | 2064 |

13×3×0.75 | 0.6 | 1.8 | 2.0 | 2.1 | 35.4 | 2196 |

14×3×0.75 | 0.6 | 1.8 | 2.0 | 2.1 | 35.4 | 2238 |

15×3×0.75 | 0.6 | 1.9 | 2.0 | 2.2 | 37.3 | 2390 |

20×3×0.75 | 0.6 | 2.0 | 2.0 | 2.3 | 41.1 | 2824 |

25×3×0.75 | 0.6 | 2.1 | 2.5 | 2.4 | 46.0 | 3679 |

30×3×0.75 | 0.6 | 2.2 | 2.5 | 2.5 | 48.5 | 4095 |

35×3×0.75 | 0.6 | 2.3 | 2.5 | 2.6 | 52.1 | 4576 |

40×3×0.75 | 0.6 | 2.4 | 2.5 | 2.7 | 54.2 | 4953 |

45×3×0.75 | 0.6 | 2.5 | 2.5 | 2.8 | 58.1 | 5495 |

50×3×0.75 | 0.6 | 2.5 | 2.5 | 2.9 | 59.1 | 5754 |

No. of Cores & Cross Section (mm2) | Nominal insulation Thickness (mm) | Nominal Inner Layer Thickness (mm) | Armour Wire Dia. (mm) | Nominal Sheath Thickness. (mm) | Overall Dia. (Approx.)(mm) | Total Weight Approx. (kg/km) |

|---|---|---|---|---|---|---|

1×3×1 | 0.6 | 1.2 | 0.9 | 1.3 | 12.5 | 307 |

2×3×1 | 0.6 | 1.4 | 1.25 | 1.6 | 20.2 | 705 |

3×3×1 | 0.6 | 1.4 | 1.6 | 1.7 | 22.0 | 924 |

4×3×1 | 0.6 | 1.5 | 1.6 | 1.7 | 23.7 | 1054 |

5×3×1 | 0.6 | 1.5 | 1.6 | 1.8 | 25.5 | 1189 |

6×3×1 | 0.6 | 1.6 | 1.6 | 1.8 | 27.4 | 1325 |

7×3×1 | 0.6 | 1.6 | 1.6 | 1.8 | 27.4 | 1376 |

8×3×1 | 0.6 | 1.7 | 1.6 | 2.0 | 31.7 | 1656 |

9×3×1 | 0.6 | 1.8 | 2.0 | 2.1 | 34.9 | 2069 |

10×3×1 | 0.6 | 1.8 | 2.0 | 2.1 | 34.9 | 2119 |

11×3×1 | 0.6 | 1.8 | 2.0 | 2.1 | 34.9 | 2170 |

12×3×1 | 0.6 | 1.8 | 2.0 | 2.1 | 35.8 | 2262 |

13×3×1 | 0.6 | 1.9 | 2.0 | 2.2 | 37.6 | 2446 |

14×3×1 | 0.6 | 1.9 | 2.0 | 2.2 | 37.6 | 2497 |

15×3×1 | 0.6 | 1.9 | 2.0 | 2.2 | 39.2 | 2629 |

20×3×1 | 0.6 | 2.1 | 2.0 | 2.4 | 43.6 | 3176 |

25×3×1 | 0.6 | 2.2 | 2.5 | 2.5 | 48.8 | 4102 |

30×3×1 | 0.6 | 2.3 | 2.5 | 2.6 | 51.5 | 4569 |

35×3×1 | 0.6 | 2.4 | 2.5 | 2.7 | 55.3 | 5104 |

40×3×1 | 0.6 | 2.5 | 2.5 | 2.8 | 57.5 | 5571 |

45×3×1 | 0.6 | 2.6 | 2.5 | 3.0 | 61.9 | 6169 |

50×3×1 | 0.6 | 2.6 | 2.5 | 3.0 | 62.8 | 6513 |

No. of Cores & Cross Section (mm2) | Nominal insulation Thickness (mm) | Nominal Inner Layer Thickness (mm) | Armour Wire Dia. (mm) | Nominal Sheath Thickness. (mm) | Overall Dia. (Approx.)(mm) | Total Weight Approx. (kg/km) |

|---|---|---|---|---|---|---|

1×3×1.5 | 0.6 | 1.2 | 0.9 | 1.4 | 13.3 | 347 |

2×3×1.5 | 0.6 | 1.5 | 1.6 | 1.7 | 22.5 | 936 |

3×3×1.5 | 0.6 | 1.5 | 1.6 | 1.7 | 23.5 | 1050 |

4×3×1.5 | 0.6 | 1.5 | 1.6 | 1.8 | 25.3 | 1202 |

5×3×1.5 | 0.6 | 1.6 | 1.6 | 1.8 | 27.3 | 1356 |

6×3×1.5 | 0.6 | 1.7 | 1.6 | 1.9 | 29.6 | 1542 |

7×3×1.5 | 0.6 | 1.7 | 1.6 | 1.9 | 29.6 | 1609 |

8×3×1.5 | 0.6 | 1.8 | 2.0 | 2.1 | 35.1 | 2155 |

9×3×1.5 | 0.6 | 1.9 | 2.0 | 2.2 | 37.7 | 2394 |

10×3×1.5 | 0.6 | 1.9 | 2.0 | 2.2 | 37.7 | 2461 |

11×3×1.5 | 0.6 | 1.9 | 2.0 | 2.2 | 37.7 | 2528 |

12×3×1.5 | 0.6 | 1.9 | 2.0 | 2.2 | 38.7 | 2639 |

13×3×1.5 | 0.6 | 2.0 | 2.0 | 2.3 | 40.6 | 2847 |

14×3×1.5 | 0.6 | 2.0 | 2.0 | 2.3 | 40.6 | 2914 |

15×3×1.5 | 0.6 | 2.0 | 2.0 | 2.3 | 42.4 | 3068 |

20×3×1.5 | 0.6 | 2.2 | 2.5 | 2.5 | 48.2 | 4163 |

25×3×1.5 | 0.6 | 2.3 | 2.5 | 2.7 | 53.0 | 4857 |

30×3×1.5 | 0.6 | 2.4 | 2.5 | 2.8 | 56.0 | 5420 |

35×3×1.5 | 0.6 | 2.5 | 2.5 | 2.9 | 60.1 | 6094 |

40×3×1.5 | 0.6 | 2.6 | 2.5 | 3.0 | 62.5 | 6616 |

45×3×1.5 | 0.6 | 2.8 | 2.5 | 3.1 | 67.3 | 7383 |

50×3×1.5 | 0.6 | 2.8 | 2.5 | 3.2 | 68.5 | 7817 |

Head Office: 2nd Floor , No. 61 , Miremad St ., Beheshti Ave ., TEHRAN-IRAN

Tel:+98 21 887 52014

Fax:+98 21 887 57639